WHAT IS MICRO CT?

How does it work?

How much does it cost?

Do I need It?

What are the common problems?

Are you new to X-ray micro-CT (computed tomography)? If so, you must have many questions. Learning a new analytical technique can be overwhelming. Purchasing new equipment is a significant investment, and the equipment selection process can be even more overwhelming, especially when you don’t have experts you can talk to.

Here at Rigaku, we design, build, sell, install, and support micro-CT scanners globally. We help people choose the right scanner, and we train equipment owners on how to collect high-quality CT images and analyze them to produce quantitative insights about their research subject. So we know a thing or two about micro-CT.

We will answer the questions our customers frequently ask us about micro-CT on this page. Hopefully, you will find the answers you were looking for below. If not, please don’t hesitate to reach out to us at imaging@rigaku.com or book a meeting with one of our experts.

Contents

- Micro-CT: What is it?

- Micro-CT: Brief history

- How micro-CT works

- Types of micro-CT scanners

- Micro-CT application examples

- Benefits of micro-CT

- Common problems of micro-CT

- Micro-CT image quality

- Micro-CT vs. other imaging techniques

- How to choose a micro-CT scanner

- Cost of a micro-CT scanner

- How to analyze micro-CT data

- Micro-CT analysis tools

- How to choose a computer for micro-CT analysis

- How to manage micro-CT data

- Own or outsource micro-CT

1. Micro-CT: What is it?

X-ray CT (computed tomography) is an X-ray imaging technique that can non-destructively image an object in 3D. It allows you to study internal structures such as pests inside a fruit, broken circuits in packaged electronics, voids and fiber distributions in composite materials, etc., without cutting the samples open.

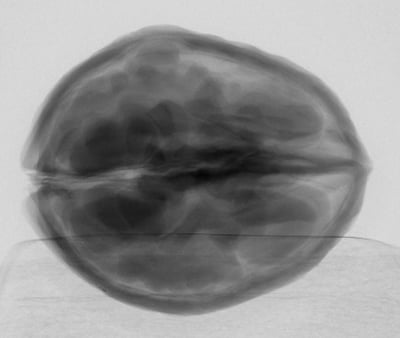

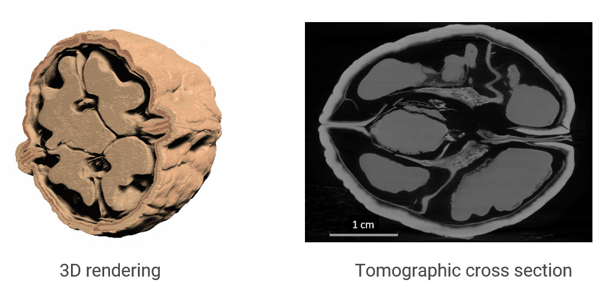

CT is often confused with radiography, but they are different. CT data is a 3D volume, while a radiograph is a 2D projection. For example, this is a radiograph of a walnut:

If something rather big is clearly broken, you can see it in a 2D projection. However, you can’t quite understand the details of the internal structures without getting a 3D image using CT. Here are CT images of the same walnut:

You can see the higher level of detail and increased amount of information a CT scan can provide compared to a 2D projection. CT measurements take longer than radiography and the instruments are more expensive, so they might be overkill for process control, but they are often worth it for scientific research, product development, and failure analysis.

There is a wide range of X-ray CT scanners with different resolutions, sample size limitations, and geometries. Generally speaking, CT scanners with micron resolution are called micro-CT scanners.

How is X-ray CT used for materials and life science?

Webinar: X-ray Computed Tomography for Materials and Life Science - Introduction

2. Micro-CT: Brief history

The best-known part of the history of CT is probably the invention of a commercial CT scanner for human brain imaging. It was developed in 1972 by Sir Godfrey Hounsfield of EMI Laboratories. He co-invented the technology with Dr. Allan Cormack, and they later shared the 1979 Nobel Prize in Physiology and Medicine.

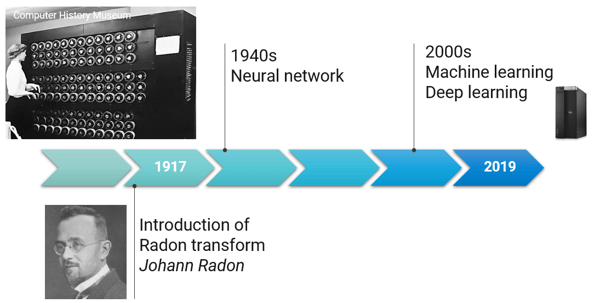

The concept of CT goes back another 55 years. In 1917, Johann Radon introduced the Radon transform, which mathematically connects 2D projections and 3D volume data. In concept, the Radon transform showed that we could use a collection of 2D projections to reconstruct 3D volume data.

Dr. Cynthia McCollough, director of the Mayo Clinic CT Clinical Innovation Center and X-ray Imaging Core, discusses the history of CT imaging in this video.

CT was first invented and used for medical imaging, but the technique migrated into materials research and industrial inspection over the years. This primarily involved invention of different types of X-ray sources and detectors.

More recent technological advancements are on the computation side. Reconstruction calculations used to convert 2D projections into a 3D volume became faster and more sophisticated, to generate higher-quality CT images.

Advancements in computational power in general and the rise of artificial intelligence (AI) based image analysis have enabled more detailed and accurate quantitative analyses of CT images in the last ten years.

The concept of neural networks first appeared in the early 1940s. Eighty years later, AI-based image analysis, such as machine learning and deep learning image segmentation, has become an everyday tool we use to analyze CT images.

How are industrial and medical CT scanners different?

Article: Industrial vs. Medical CT Scanners: What Are the Differences?

3. How micro-CT works

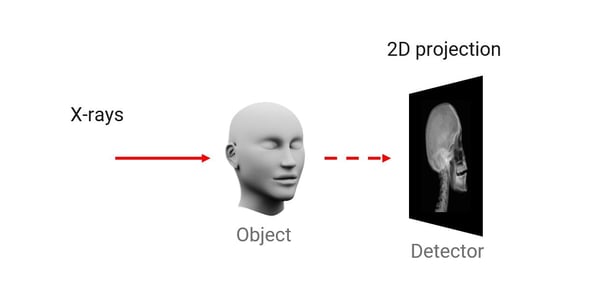

A CT image is a 3D map of a material’s absorption rate closely related to its density. We cannot measure the 3D map directly; instead, we need to measure 2D projections and reconstruct the 3D map.

An object absorbs X-rays at a varying rate depending on the material’s absorption rate for transmitting X-rays’ energy. Given the same X-ray energy, the denser the material is, in general, the more X-rays are absorbed. Also, the thicker the object is, the more X-rays are absorbed.

By putting an X-ray source on one side of the object and a 2D detector on the other, we can capture a 2D projection showing varying levels of X-ray absorption.

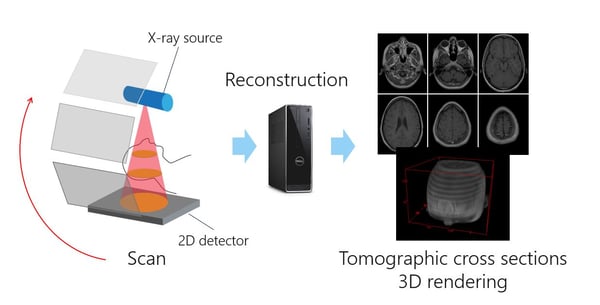

You can rotate the object and obtain multiple 2D projections. Alternatively, you can rotate the X-ray source and the detector around the object. The former is more common for micro-CT, especially when high resolution is required. The latter is more common for medical CT to avoid rotating the patient.

The figure below shows an example of a head CT scan. After a scan is complete, you can put the obtained 2D projections into a reconstruction program to "reconstruct" the 3D image.

How do you collect micro-CT images?

Workshop: Micro-CT Data Collection Techniques Part 1

Workshop: Micro-CT Data Collection Techniques Part 2

4. Types of micro-CT scanners

There are several ways to categorize micro-CT scanners.

Size

Micro-CT scanners come in various sizes, but we can categorize them as benchtop and full-size models. Benchtop models are less expensive, require less maintenance, and are easier to use. However, the X-ray energy is limited to 130 kV in most cases. The sample size is also limited.

Many full-size models are compatible with 160 kV or 225 kV X-ray sources and accommodate larger samples. These tend to be more expensive and require more maintenance and expertise.

Geometry

Most micro-CT scanners have the X-ray source and the detector fixed and rotate the sample, with everything aligned on a horizontal straight line.

However, some keep the sample stationary and rotate the X-ray source and the detector vertically around the sample. This is called a gantry system, often used for in-vivo scans of live animals.

A few CT scanners use a horizontal gantry system. In this geometry, the sample stays stationary, and the X-ray source and the detector rotate horizontally around the sample. This type of CT scanner tends to be more expensive, but this is the ideal geometry for high-speed 4D (time-resolved) CT experiments and in-situ CT, especially when fluid is involved.

Magnification mechanism

Most micro-CT scanners use cone beam geometry for image magnification. Cone beam geometry uses the divergence of the X-ray beam and X-ray source, sample, and detector distances to magnify the projection image. It is a simple and inexpensive method.

Some micro-CT scanners use an optical lens for magnification. This method is called parallel beam geometry. In this case, X-ray divergence is limited by a collimator to make the beam pseudo-parallel. The transmitted X-rays are converted into visible light by a scintillator. Then the projection image in visible light is magnified by a lens before it hits the detector.

You can also combine the cone beam and optical magnification. The benefit of this method is that you can achieve high resolution even when the sample is large. This is often challenging for cone beam and parallel beam geometries.

X-ray energy

Most micro-CT scanners use X-ray sources from 80 kV to 160 kV. Some larger scanners can go up to 225 kV or higher. Higher excitation voltage helps to image larger and denser samples, but it also means higher costs and limitations when imaging small and light samples well.

A few micro and submicron-CT scanners use characteristic radiation, which is pseudo-monochromatic. In this case, the X-ray target material defines the X-ray energy rather than the excitation voltage. Commonly used target materials include chromium for 5.4 keV, copper for 8 keV, and molybdenum for 17 keV.

Contrast method

Most micro-CT scanners use absorption contrast imaging. Some CT scanners can use phase contrast, although these are usually more expensive. Phase contrast imaging can enhance the contrast of very lightly-absorbing materials such as animal and plant tissues.

5. Micro-CT application examples

X-ray CT can be useful if you need to image the internal structure of something non-destructively. The application of micro-CT spans a wide range, even outside medical use.

Here are several representative examples.

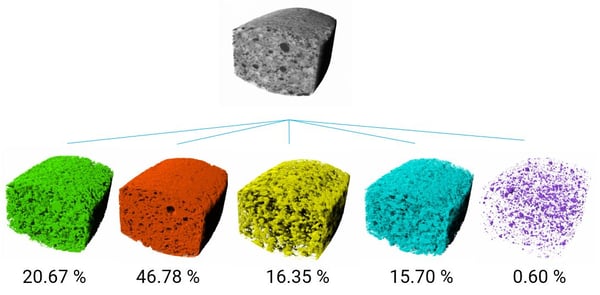

Phase volume fraction analysis

Different phases often show different gray levels in CT images due to their different absorption rates. That means that you can analyze the volume fraction.

Here is an example of a volume fraction analysis of a multivitamin tablet.

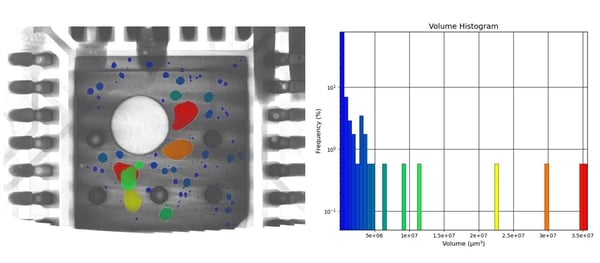

This analysis can also be applied to composites, geological samples, food, or any mixture of different materials. Void fraction calculations are just one of the most common applications. Below is an example of solder joining void analysis.

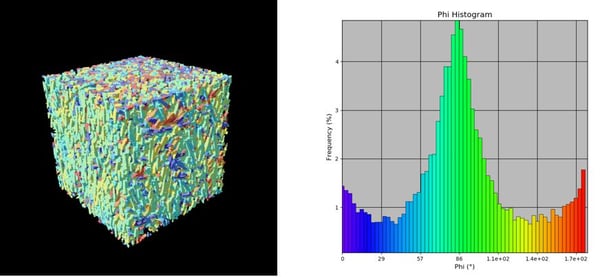

Particle, pore, and fiber analysis

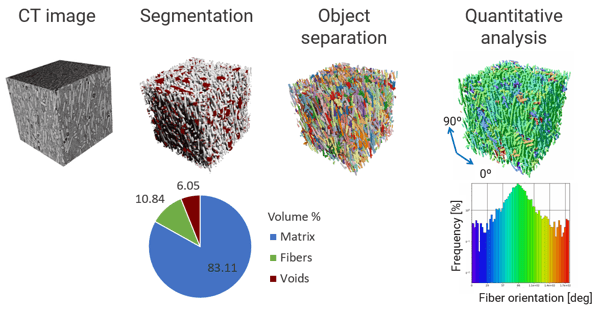

Particles, pores, and fibers can be segmented in CT images, and their properties can be investigated. For example, you can analyze particle size distribution in pharmaceutical tablets, pore networks in reservoir rocks, pore size distribution in foams, or the orientation of fibers in composites.

Below is an example of orientation analysis of carbon fibers in CFRP (carbon fiber reinforced polymer).

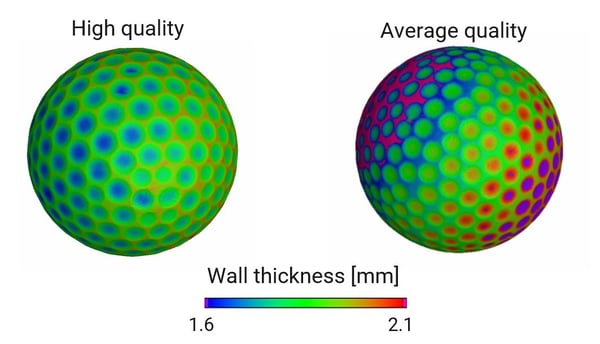

Coating and wall thickness analysis

Coatings and walls, including those inside an enclosed object, can be imaged using CT. They can be segmented and their thickness distributions and any discontinuity or delamination can be identified.

Below are the analysis results of the wall thickness distribution of two grades of golf balls.

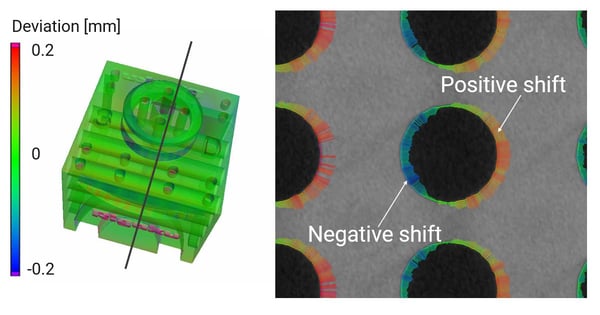

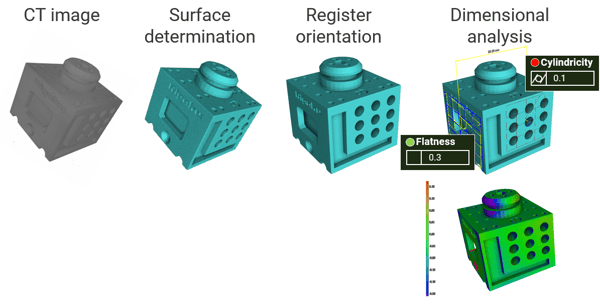

Metrology and dimensional analysis

CMMs (coordinate measuring machines) and optical scanners are often used to analyze the dimensions of parts. While these techniques cannot reach the internal structures, CT can image the entire volume of the parts and enable internal dimensional analyses.

Below is an example of an actual (CT scan) and nominal (CAD) dimensional comparison of a 3D-printed plastic part.

How can we use CT to analyze dimensions?

Webinar: X-ray Computed Tomography for Materials and Life Science - Metrology Applications

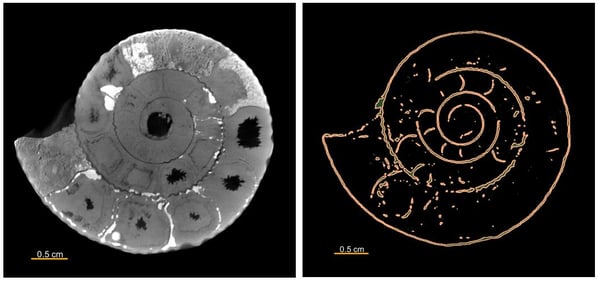

Non-destructive 3D imaging

As we saw in the examples above, CT images are segmented, and properties and dimensions of interest are quantitatively analyzed. However, inspection of 3D images can tell us a lot. CT is used in archeology and other areas where people need to see the internal structures of rare or valuable samples that need to stay intact.

Below is an example of the internal structure of an ammonite fossil revealed by a CT scan.

6. Benefits of micro-CT

The number one benefit of micro-CT is its ability to non-destructively image objects, including their internal structures, in 3D. We saw several examples in the previous section. Here are a few more cases where CT can provide invaluable insights.

You can run countless dissolution tests or chemical analyses of a tablet that fails to dissolve at the desired rate to determine what is wrong or you can scan the tablet using micro-CT and see what is wrong, as in this example:

Because CT is non-destructive, you can scan the same sample multiple times over an arbitrary time period or scan it before and after a change. For example, if you use a composite or foam product and want to see the damage that builds up over time, you can do so on the same sample, as in this example:

7. Common problems of micro-CT

Micro-CT is not almighty; it has limitations. You might need an electron microscope to achieve nanometer resolution. You might have to settle for a CMM or an optical scanner to analyze large samples. Or the sample density could cause problems, preventing you from getting good contrast.

Here are the common problems or limitations of micro-CT:

- Resolution is too low

- Can't scan the whole sample

- CT image is all too dark or too bright

- There is no density contrast

- Scans take too long

- Files are too big

- Analysis is too involved

In some cases, micro-CT might not be the right solution but, in other situations, there are ways to solve these problems. Read this article about common problems and how to avoid them before deciding if micro-CT is the right solution for you:

8. Micro-CT image quality

For many analytical techniques, the definition of data quality is rather vague and not well understood. Micro-CT is not unique in this regard.

It is essential to understand how to evaluate CT image quality when selecting a micro-CT scanner for your research or when trying to achieve accurate results.

Here are the key attributes of CT images:

These factors are interrelated, and improving one can worsen others. For example, increasing the resolution often requires reducing the FOV.

The key is understanding which quality matters the most for the specific analysis you want to conduct; then, you can optimize the measurement conditions to maximize that particular quality while compromising other factors.

The following articles will help you understand how to do that:

How can I improve image quality?

Article: How to Improve the Resolution of X-ray CT Images

Article: How to Improve the Signal-to-noise Ratio of X-ray CT Images

9. Micro-CT vs. other imaging techniques

The imaging technique most often compared to micro-CT is scanning electron microscopy (SEM). Both can provide high-resolution images of various types of samples.

The advantage of micro-CT is its ability to provide a 3D image for a relatively large volume or FOV, up to hundreds of millimeters, while SEM requires a relatively small sample and has limited scanning depth. It also requires a focused ion beam (FIB) to remove layers to obtain 3D images.

Micro-CT usually requires minimal sample preparation (often none at all) because the measurement occurs in the air, and no electric conductivity is required. Meanwhile, SEM requires sample preparation, such as drying and coating, to put it in a vacuum and ensure electric conductivity on the sample surface.

The downside of micro-CT is the lack of elemental analysis capability. SEM can easily map the elemental makeup of a sample, while elemental analysis is not available for most CT scanners.

For a more detailed comparison, read this article:

10. How to choose a micro-CT scanner

Most micro-CT analysis needs can be satisfied by a horizontal cone beam geometry system. Here are some general guidelines for choosing the right one:

The right CT scanner type depends on the sample type and size of the features you want to image; in other words, the required FOV and resolution. Keep in mind that the spatial resolution, or the size of the smallest feature you can see, is limited to the range of about FOV/1000 to FOV/3000.

The X-ray energy, roughly half of the excitation voltage, depends on the sample size and density. You can use the following guidelines:

- Larger or heavier samples, such as steel or copper, thicker than a few mm → Choose an X-ray source with a high excitation voltage of 130 - 225 kV.

- Small to medium-sized (5~200 mm) plastics, polymers, composites, wood, etc., or small (a few mm) and light metals (aluminum, for example) → Choose an X-ray source with a medium excitation voltage of 60 - 130 kV.

- Relatively small (1~10 mm) organic materials, foams, etc. → Choose an X-ray source with a medium excitation voltage of 60 - 90 keV or consider using characteristic X-rays of 5.4 - 17 keV.

Here are some special cases where you want to consider other options:

- Need to scan very large and dense objects such as car engines → Consider 400 kV or MeV CT X-ray sources.

- Need better than 1-micron resolution. → Consider submicron or nano CT scanners equipped with optical lenses, Fresnel zone plates, or super mirrors.

- Need to do high-speed 4D CT → Consider a horizontal gantry geometry.

- Need to scan live animals in-vivo → Consider an in-vivo compatible gantry system.

Regardless of the technical requirements, the cost of a micro-CT scanner is always important. We will discuss that in the next section.

Lastly, always get test scans on your samples before purchasing a CT scanner. You can get an idea of what a scanner is capable of from its spec sheet, but it is a significant investment. Most manufacturers run test scans for free, so why not?

11. Cost of a micro-CT scanner

The price of a CT scanner, in general, varies from $200K to $2M. Standard horizontal cone beam geometry micro-CT scanners cost $200K to $700K.

Why such a wide range? Mainly because the price of an X-ray source can vary widely depending on the excitation energy and power. Secondly, the size of the sample stage and radiation enclosure can vary greatly.

If you need better than 1-micron resolution, need to scan large and dense samples, or need full 4D or in-situ CT capabilities, you should expect $1M and over. If you need only a few microns to submillimeter resolution, your samples are organic or other light materials and can fit on your palm; then, you will be most likely happy with a benchtop CT scanner ranging from $200K to $300K.

The initial purchase of the CT scanner is the most significant part of the expense, but you should also consider the cost of analysis software, training, maintenance, data storage, etc. This article reviews all costs involved in introducing and maintaining a CT scanner:

What makes CT scanners expensive? What other costs should I consider?

Article: How Much Does a Micro CT Scanner Cost?

12. How to analyze micro-CT data

The way we analyze CT data differs depending on whether we use CT for materials research or dimensional analysis.

For materials research, we segment the CT images by labeling individual voxels as polymer, void, and carbon fiber, for example. Meanwhile, for dimensional analysis, we need to use a method called ISO-50 surface determination to identify the object’s surface location with a resolution beyond the voxel resolution.

As you see in the overview below, image segmentation is the first step of the analysis process for materials research. You can segment the CT images into different phases by thresholding the gray levels. When thresholding fails due to noise and low contrast, etc., you can use machine or deep learning segmentation.

Once you segment the image, you can calculate the volume fractions.

Then, individual objects—fibers, for example—need to be separated before analyzing properties such as fiber orientation and particle size distributions.

How can I analyze CT data for materials research?

Webinar: X-ray Computed Tomography for Materials and Life Science - Introduction

To analyze dimensions, you start with surface determination using the ISO-50 method, as you see in the outline below:

Once the surface is determined, you can orient the part to align it to the measuring coordinate axes. Then you can start measuring dimensions, evaluating geometrical tolerances (GD&T analysis: geometric dimensioning and tolerancing analysis), or comparing the actual (CT) to the nominal (CAD) dimensions.

Many commercial software packages are available. We will review them in the next section.

How can we use CT to analyze dimensions?

Webinar: X-ray Computed Tomography for Materials and Life Science - Metrology Applications

13. Micro-CT analysis tools

Most commercial software packages have a specific, focused area of analysis. Here are the tools we use daily and recommend:

Dragonfly by Object Research Systems for materials research

Dragonfly is relatively inexpensive and easy to use. They also offer a free non-commercial license. Although affordable, it is very powerful and covers most analysis needs. We recommend it for materials and life science CT data analysis.

One of the best parts of Dragonfly is the segmentation wizard. It makes deep learning image segmentation accessible to beginners and helps to deal with challenging image segmentation.

VGSTUDIO by Volume Graphics for dimensional analysis

VGSTUDIO is the de facto industry standard for metrology and dimensional analyses. It fully supports geometric dimensioning and tolerancing (GD&T) analysis and nominal (CAD) versus actual (CT) comparison.

Their algorithms have been tested and verified by PTB (Physikalisch-Technische Bundesanstalt) and NIST (National Institute of Standards and Technology).

For a more comprehensive list of recommended software, see this article:

14. How to choose a computer for micro-CT analysis

Computer specs matter. A micro-CT image is typically a few GB but can be over 20 GB. All the image processing and detailed analyses we need to run on these large files are computationally demanding.

The computer can make a difference between being able to analyze high-quality CT data as is and having to compromise the resolution and accuracy.

Although it is an important decision, choosing the right computer is not exactly a straightforward process. The RAM size, type of GPU, etc., need to be compatible with the analysis software and your CT image size.

Here are seven things to consider when buying a computer for CT image processing:

- Which image analysis software to use

- Range of the image size you need to process

- Processor (CPU)

- System memory (RAM)

- Graphics card (GPU)

- Data storage

- Price

The first two items should dictate what type of CPU, RAM, GPU, and data storage are required, which will dictate the price.

Once you know which analysis software to use and have an idea about the image file size, you can follow these three steps to choose the right computer:

- Check the analysis software’s recommended system requirements. (Never go with the minimum requirements.)

- Give these requirements to a computer manufacturer representative and have them configure a computer.

- Give that computer configuration to the software manufacturer representative to get their stamp of approval.

If you want to configure a computer or understand more about the differences among different types of each component, this article will help you:

How should I choose a computer for CT image processing?

Article: 7 Things to Consider When Buying a Computer for CT Image Processing

15. How to manage micro-CT data

One of the most common questions our customers ask us after using a CT scanner for a while is, "How should I manage these huge CT image files?"

It is not easy to manage files when you can generate 100 GB of data daily. The TB hard drives fill up quickly, so start planning early.

One decision to make at an early stage is to use in-house storage or a cloud storage service. Here are recommendations for in-house storage. We recommend a service created specifically for CT image storage if you choose cloud storage. Here are more details about data storage and cloud service:

Wherever you decide to store your data, here is a general good practice tip: Categorize data into “still working on” and “ready to archive” groups. The former is the data you want to go back to and keep analyzing or from which you still need to generate a report. The latter is the data you’ve finished analyzing and don’t need to access often.

Keep the “still working on” data on the local data drive of the computer you use for image analysis for easy access. You can move the “ready to archive” data to long-term storage—in-house or cloud-based—to free up space on the data drive.

16. Own or outsource micro-CT

Should you purchase and own your micro-CT scanner? Or outsource the work to a contract service lab? That depends on how many samples you need to scan per day, week, or month.

Let’s do the math. We will use $500 per sample as the market price for contract service. If you want to analyze five samples per month, you will spend $300K in ten years. That is already more than the price of a benchtop CT scanner. If you have a few samples per week, ranging from 10 to 30 per month, the total cost quickly approaches a $M level.

|

# of samples per month |

Service per sample |

Cost per year |

Cost per 10 year |

|

5 |

$500 |

$30,000 |

$300,000 |

|

10 |

$500 |

$60,000 |

$600,000 |

|

30 |

$500 |

$180,000 |

$1,800,000 |

Now, let’s think about owning a CT scanner. Most scanners last more than ten years. We will use 7% of the scanner price as the cost of ownership per year. In the calculation below, you can see even with the $800K CT scanner, the cost per 10 years is less than the cost of outsourcing 30 samples per month.

|

Initial cost |

Cost of ownership per year |

Cost per 10 year |

|

$250,000 |

$17,500 |

$425,000 |

|

$500,000 |

$35,000 |

$850,000 |

|

$800,000 |

$56,000 |

$1,360,000 |

This comparison obviously is not this simple, although cost should be a major determining factor. Here are the other pros and cons of each choice:

Owning a CT scanner

Pros:

- You can do the best job answering your research and analysis questions by doing the right analyses. Sometimes things get lost in translation, and a contract research lab’s report might not satisfy you.

- You can run a scan and get the results whenever you want.

- An increase in demand doesn’t increase the cost much.

- You don’t need to share your results with outside organizations.

Cons:

- You need to secure the initial purchasing cost.

- You need to maintain the scanner.

- You need to learn how to run CT scans and analyze results.

Outsourcing CT analysis

Pros:

- The expense is spread out over time.

- You don’t need to maintain the scanner.

- You don’t need to learn how to run CT scans and analyze results.

Cons:

- A contract research lab might not understand your analysis needs fully, and their report might not answer your research and analysis questions.

- You might have to wait a long time for the results.

- If the demand increases, the cost increases as well.

- You need to share your results with outside organizations.

We hope this article helped to answer your questions. At Rigaku, we have been designing and building X-ray instruments for over 70 years. Our team of sales and application specialists can help you find and configure the right CT scanner for your research. You can also try CT scans on your samples and schedule a demo.

If you have questions or are interested in testing one of our CT scanners, you can email us at imaging@rigaku.com or book a meeting with one of our experts.