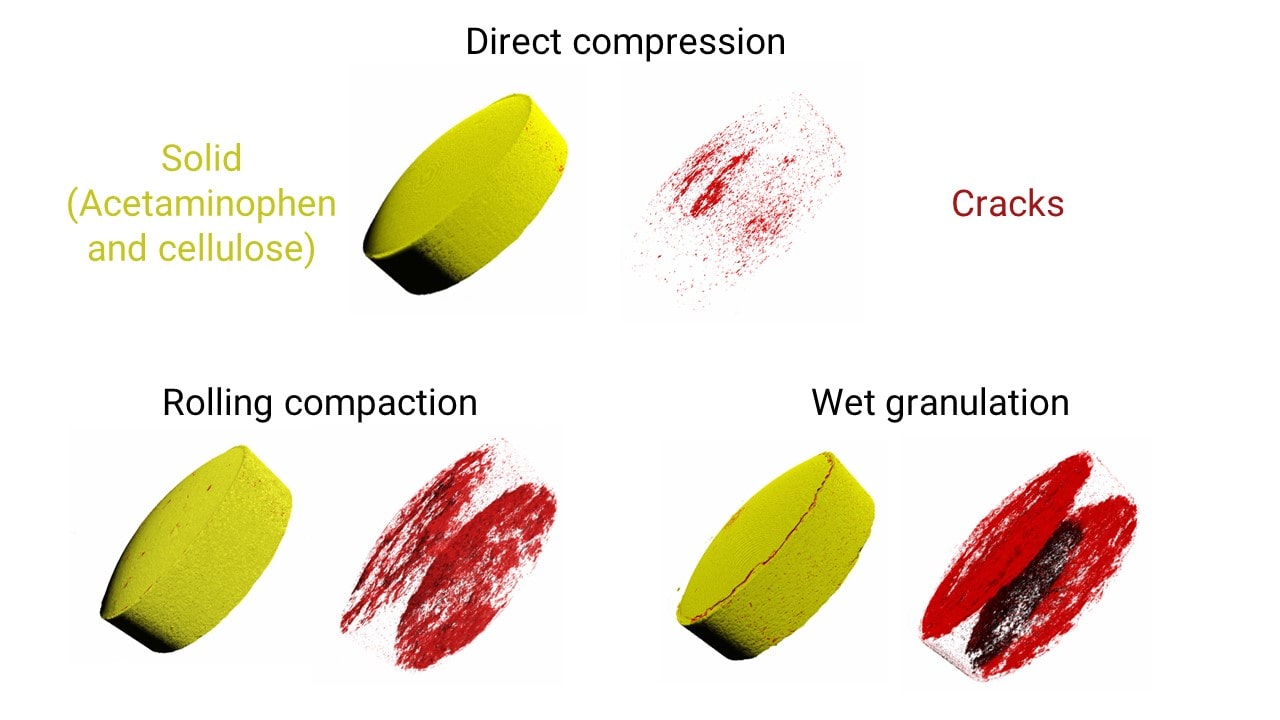

COMPRESSION METHODS COMPARISON

About the sample: Compressed tablets

Compression is one of the most widely used methods to make tablets. The compression processes often face common manufacturing issues, such as sticking, picking, capping, and lamination, and it is essential to optimize the process before scaling up the production. X-ray CT (computed tomography) can visualize cracks non-destructively to understand how they occur and cause capping issues.

Analysis procedure

- In this example, acetaminophen and cellulose tablets were prepared using three compression methods and scanned using a micro-CT scanner, CT Lab HX.

- The crack widths were measured from the CT image.

- The cracks and voids were segmented and visualized in 3D.

1. CT scan

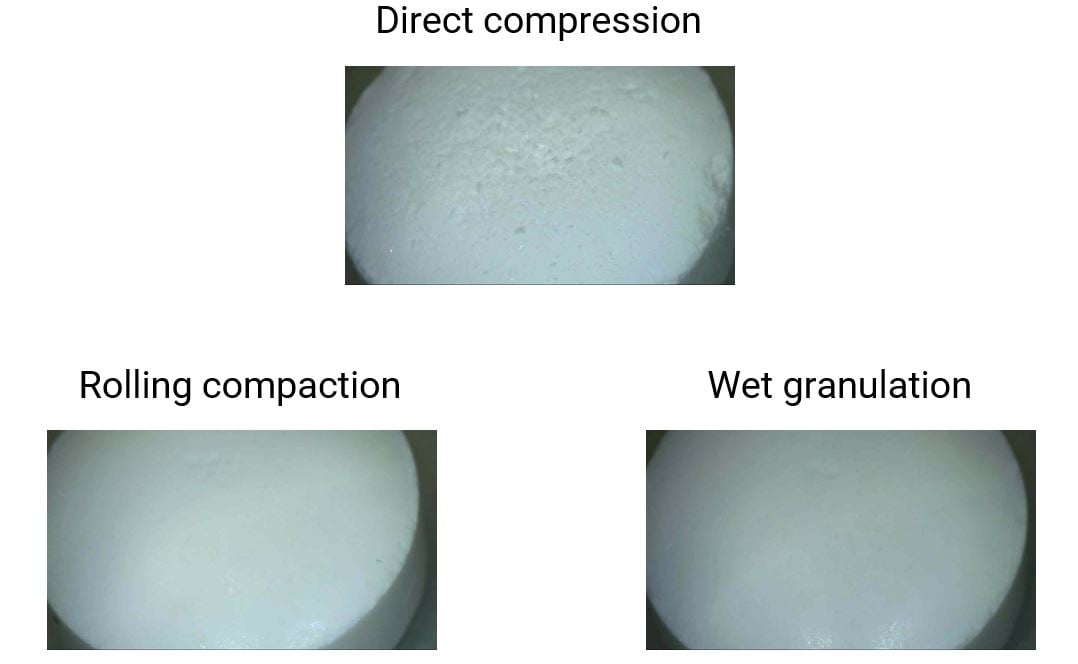

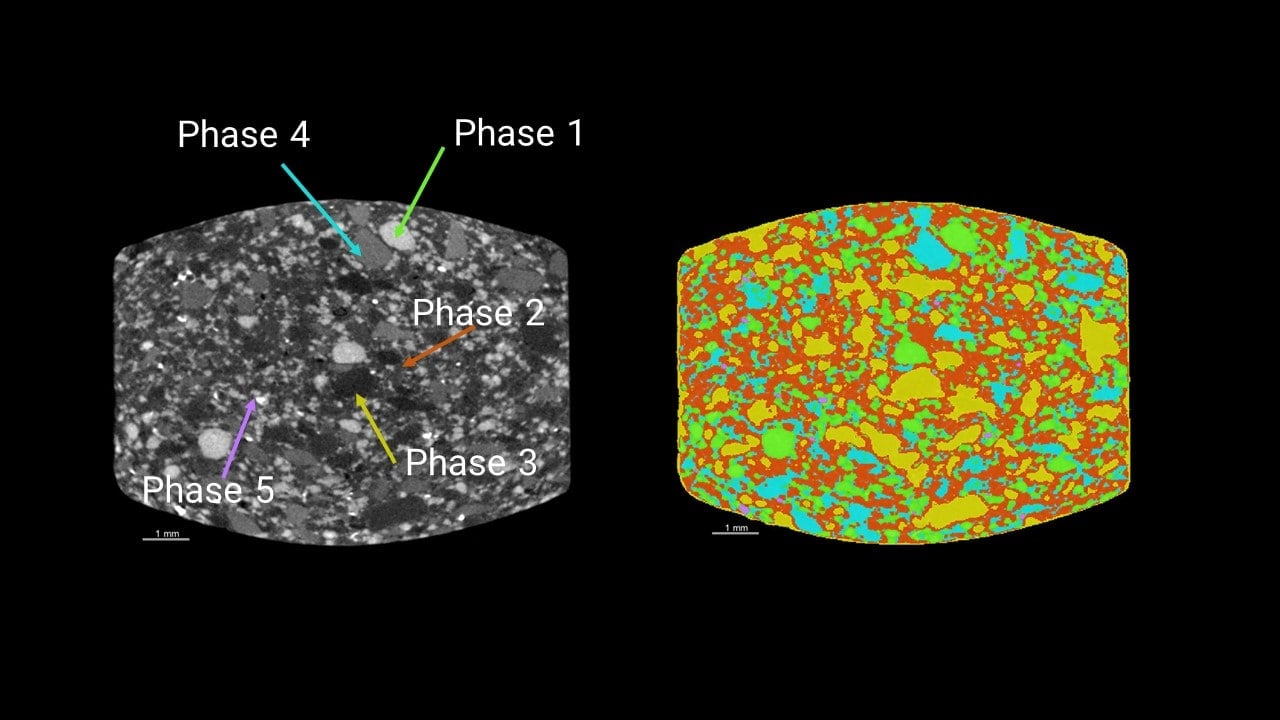

Acetaminophen and cellulose tablets were prepared using direct compaction, rolling compaction, and wet grinding methods. All tablets were scanned to produce the 3D grayscale CT images.

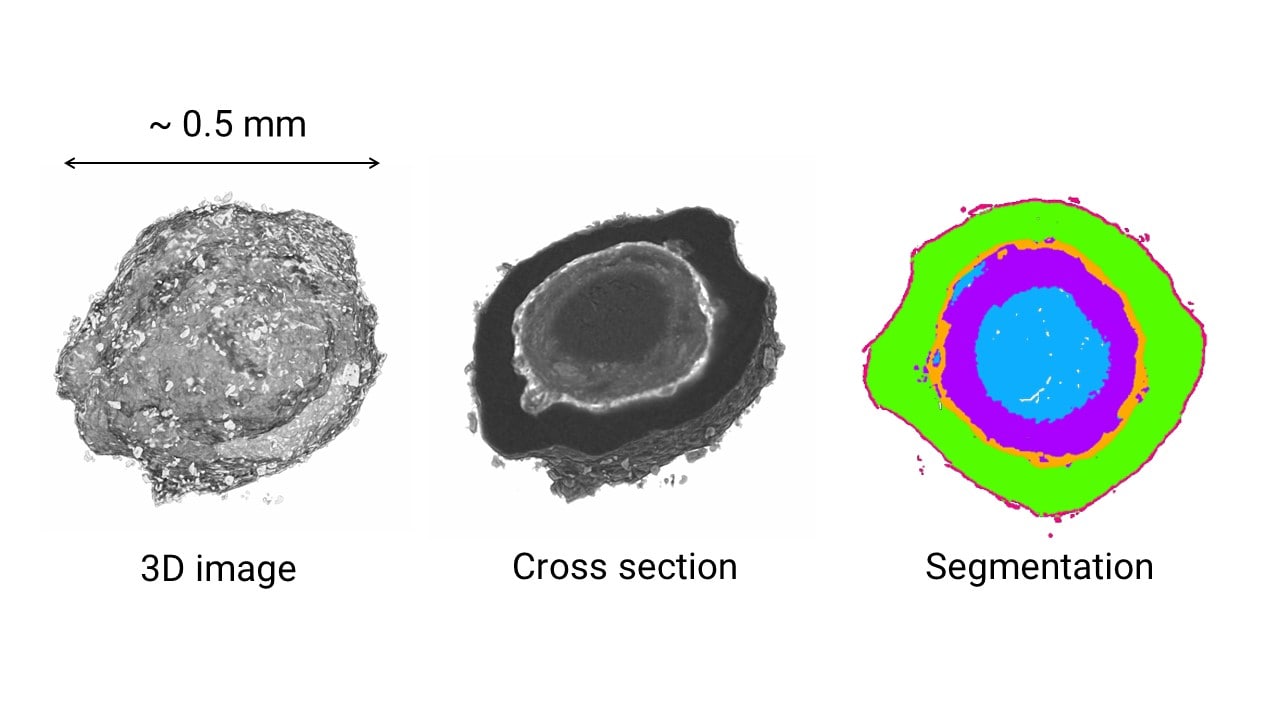

The appearances of the tablet surface are shown in the figure. The direct compaction tablet looks crumbling while the rolling compaction and wet grinding tablets have smooth surfaces.

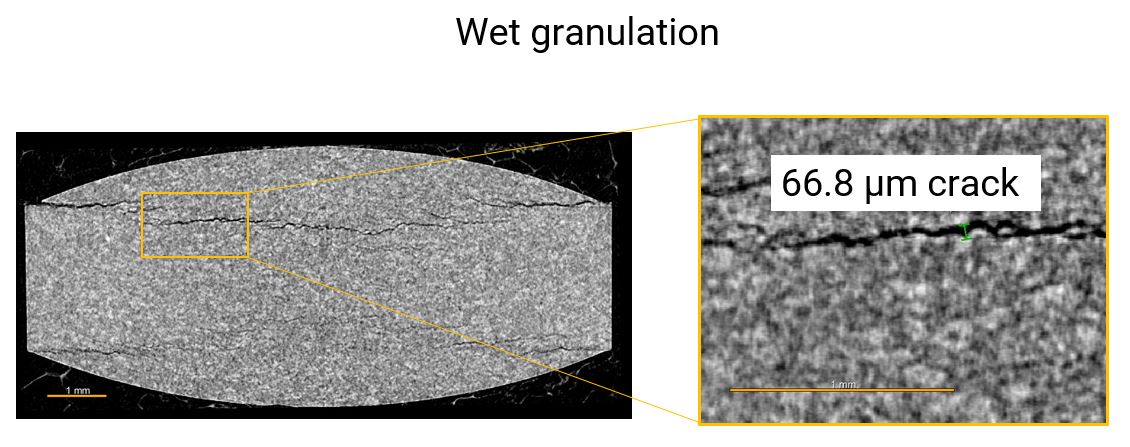

2. Crack width measurement

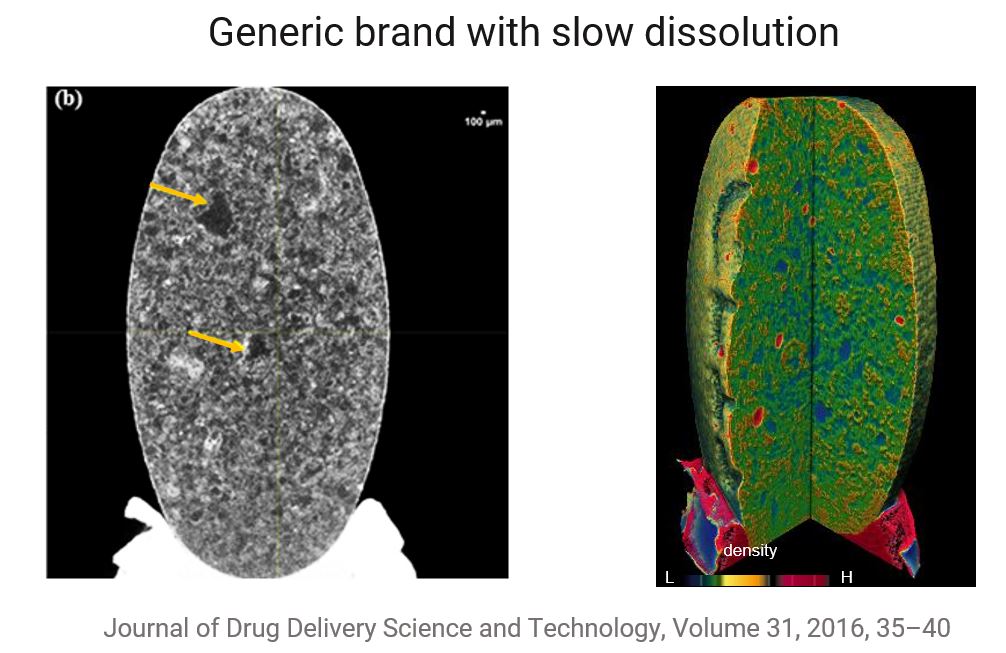

While the direct compaction tablet did not show any cracks, the wet grinding tablet showed large cracks up to 100 microns wide. An example of a crack is shown in the figure. The cracks start at the corner of the tablet and run horizontally, indicating that this method will most likely cause capping in production.

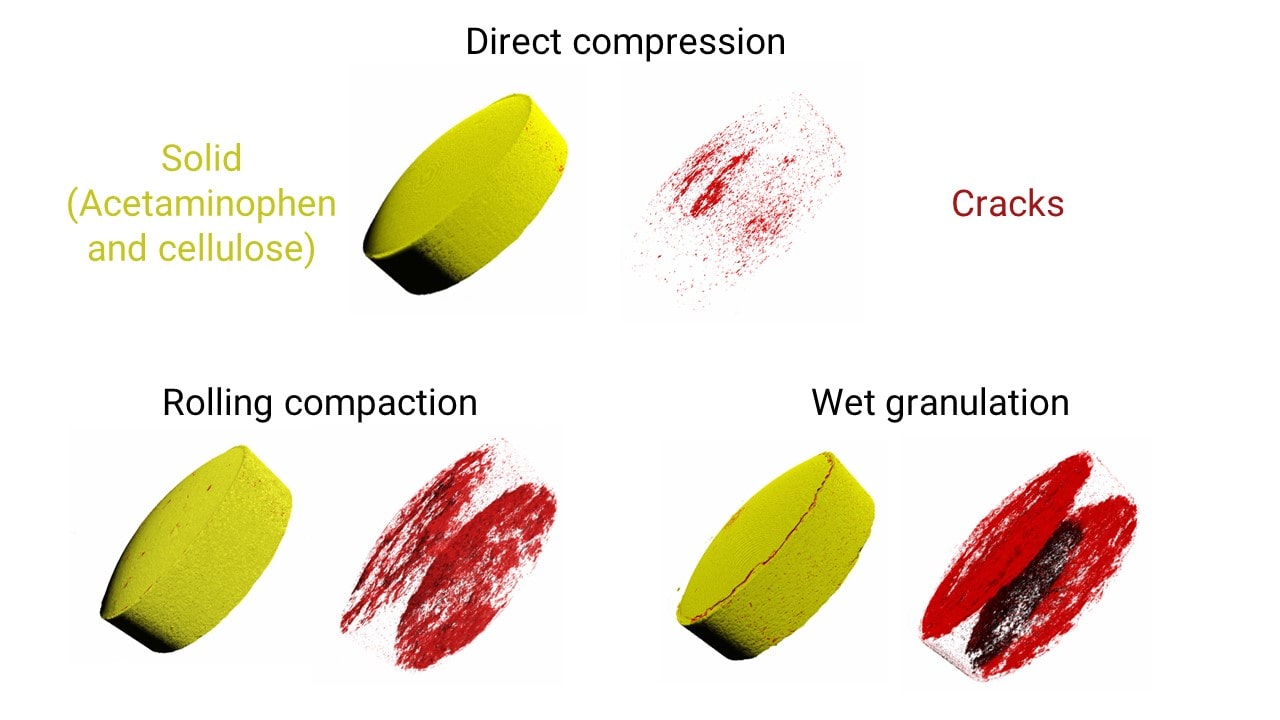

3. Crack segmentation and visualization

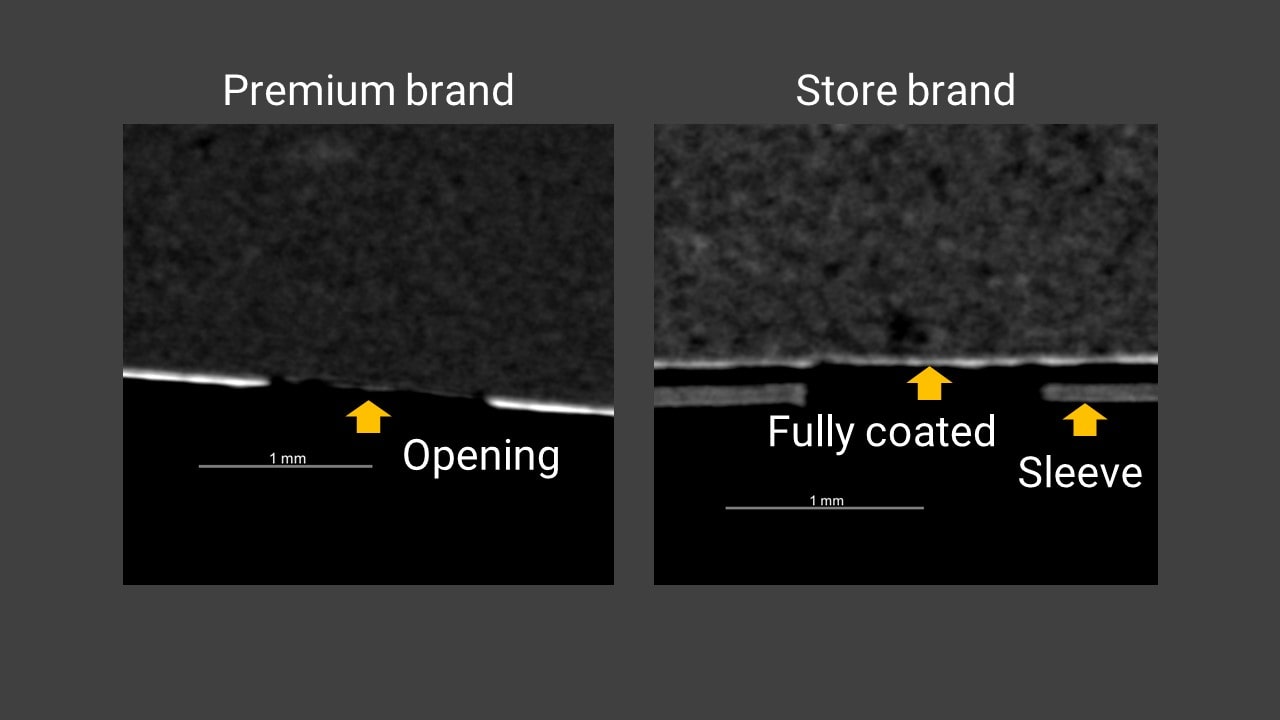

Cracks and voids were segmented and visualized in 3D for the three tablets. The direct compaction tablet showed no apparent cracks. Both the rolling compaction and wet grinding tablets had cracks, which are a sign that capping is starting. The wet grinding tablet's cracks are more significant and wider than that of the rolling compaction.

More Pharmaceutical Application Examples

Watch an on-demand webinar about X-ray CT pharmaceutical applications.

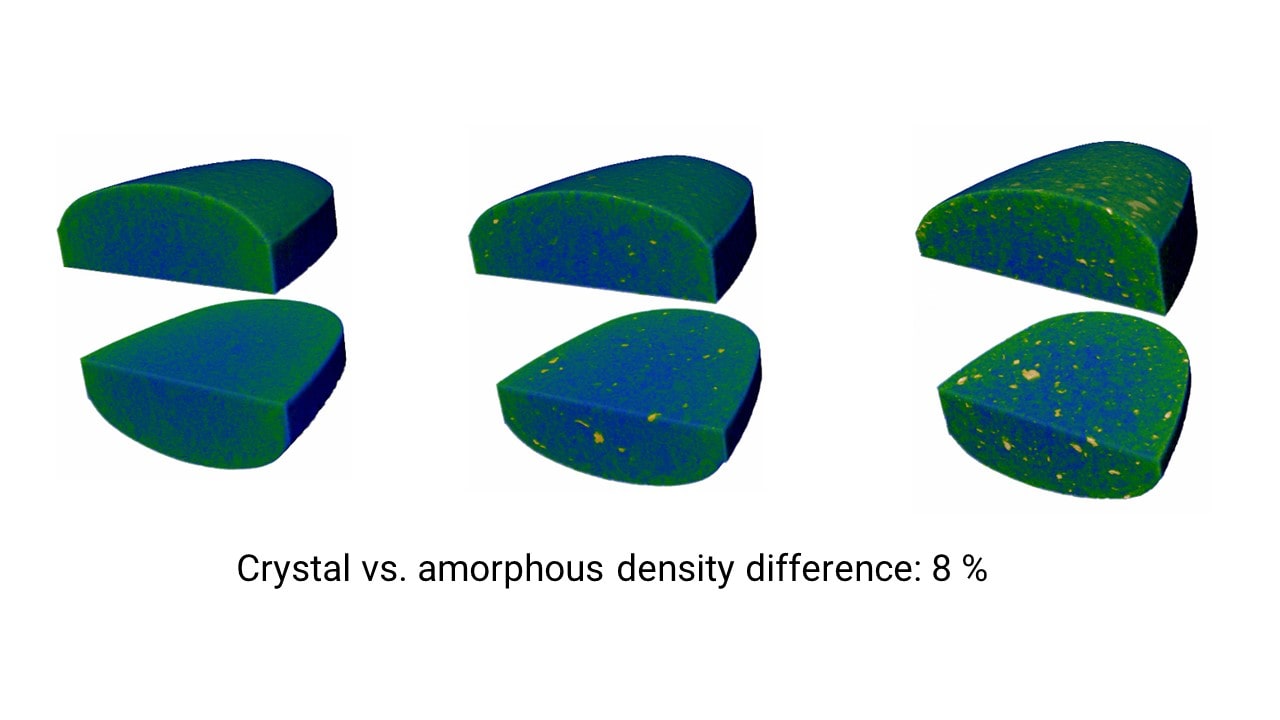

Tablet crystallinity analysis

Application Note

Brand name vs generic atorvastatin tablets comparison

Application Note

Microparticle coating analysis

Application Note

Rapid-release pain medication capsule comparison

Application Note

Multivitamin tablet analysis

Application Note

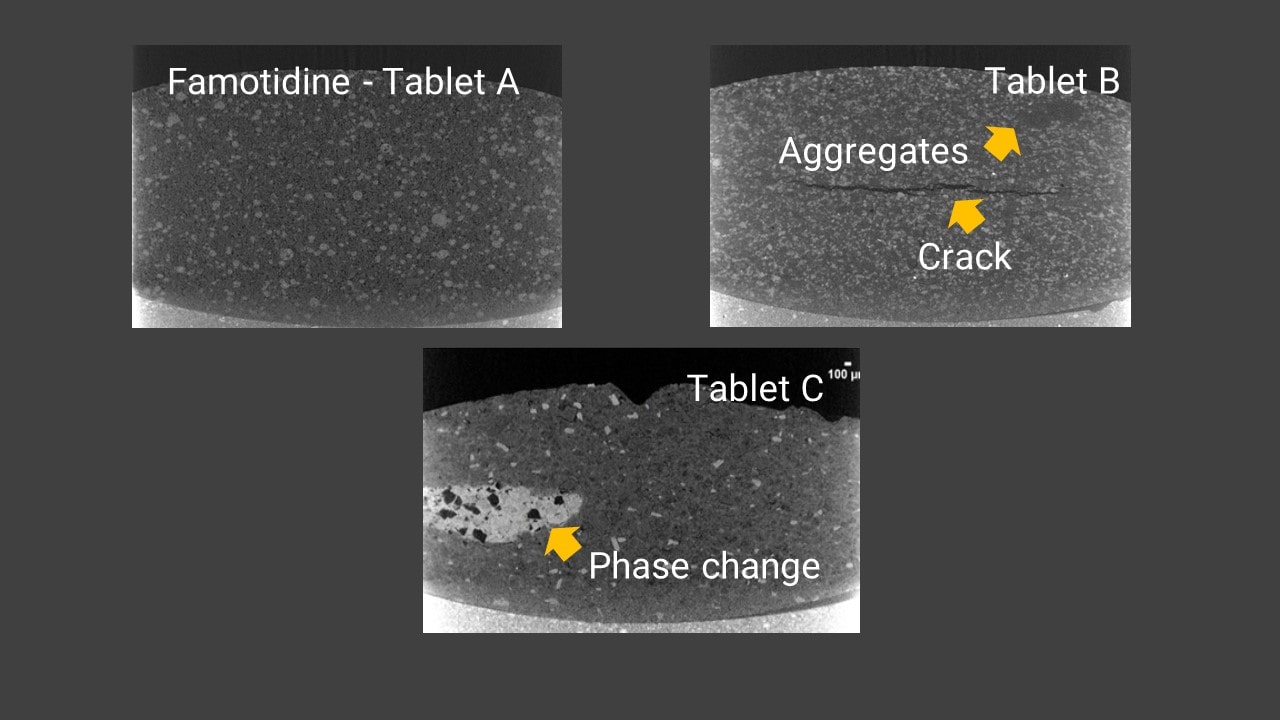

Famotidine tablet comparison

Application Note

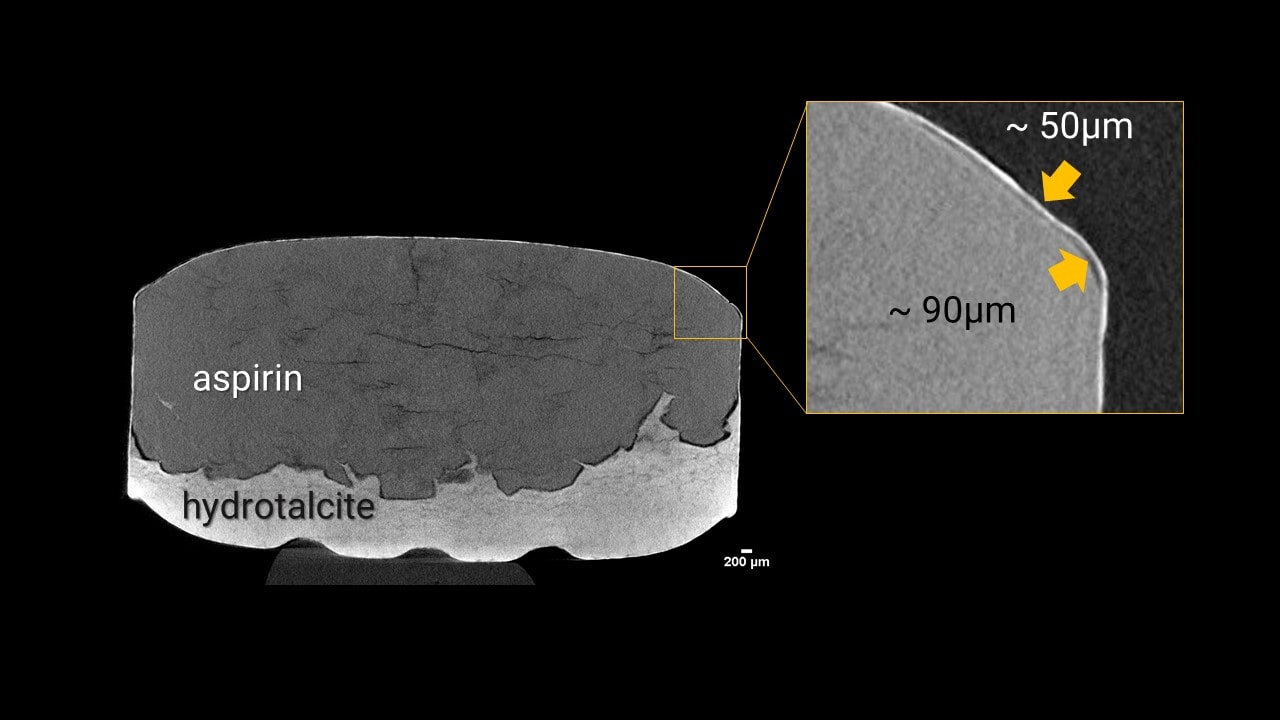

Aspirin tablet coating delamination

Application Note

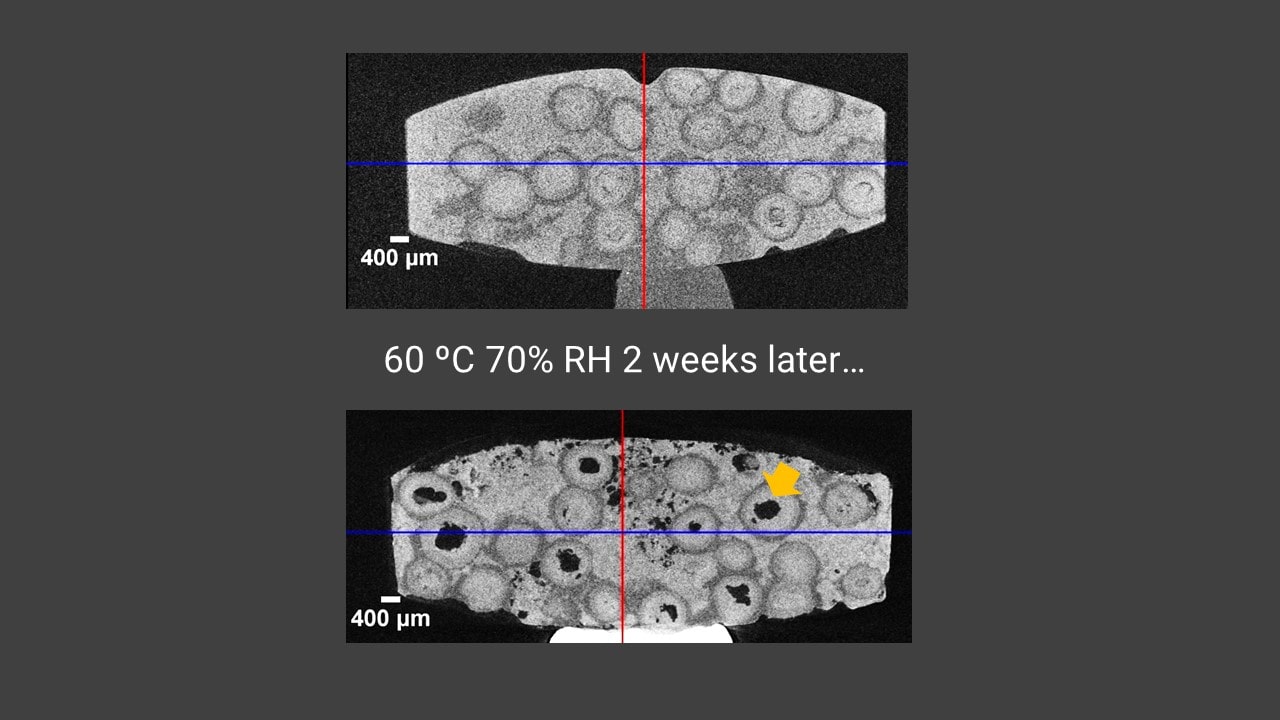

Degradation of sustained-release dosage tablet

Application Note

Compression methods comparison

Application Note