METROLOGY APPLICATIONS

X-ray CT analysis for dimensional analysis

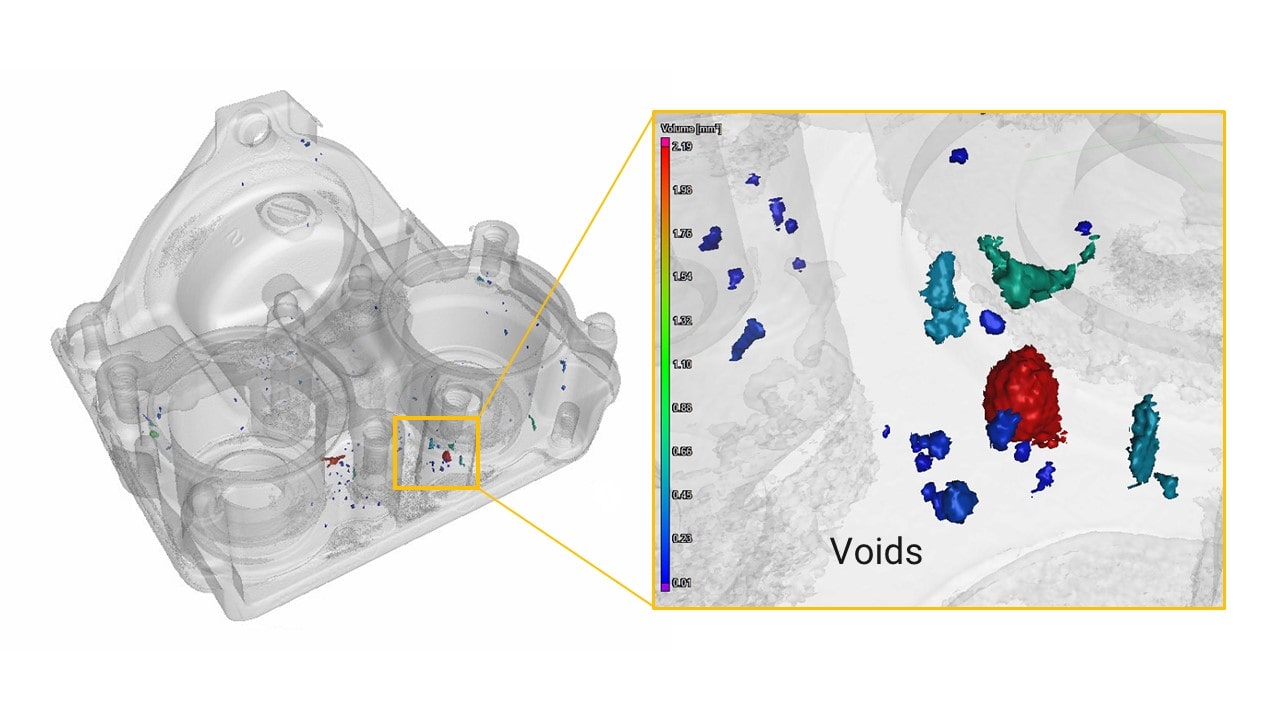

X-ray CT computed tomography is a non-destructive 3D imaging technique. It can scan the entire volume of various parts, allowing analysis of external shape, internal shape, and defects such as voids, cracks, and inclusion.

Application examples:

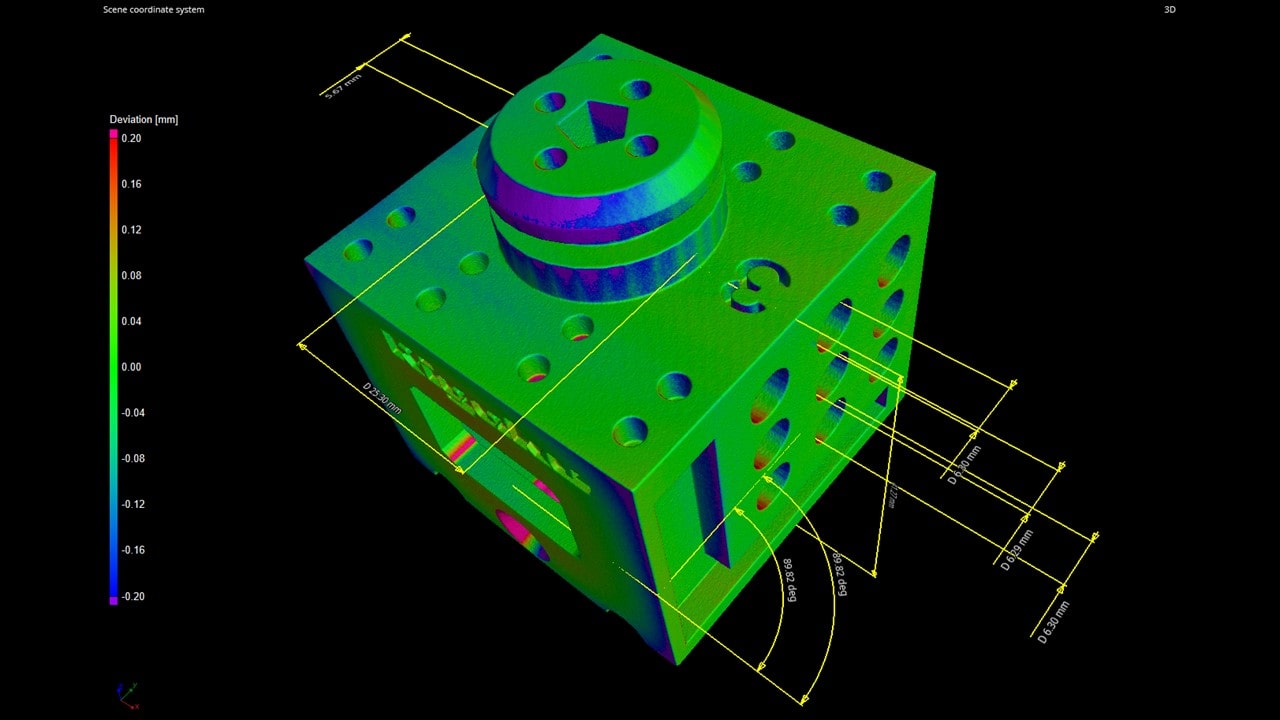

- Dimensional analysis

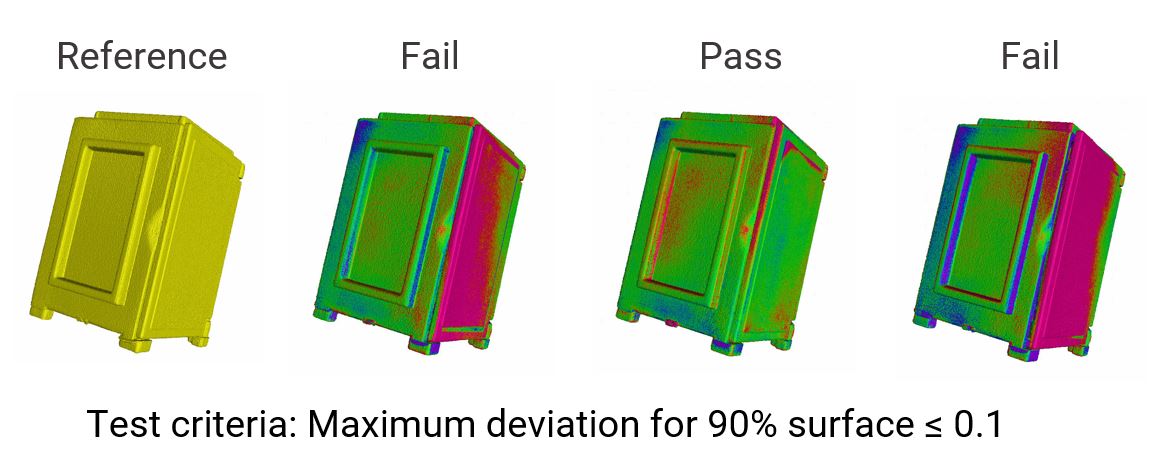

- Nominal versus actual comparison analysis

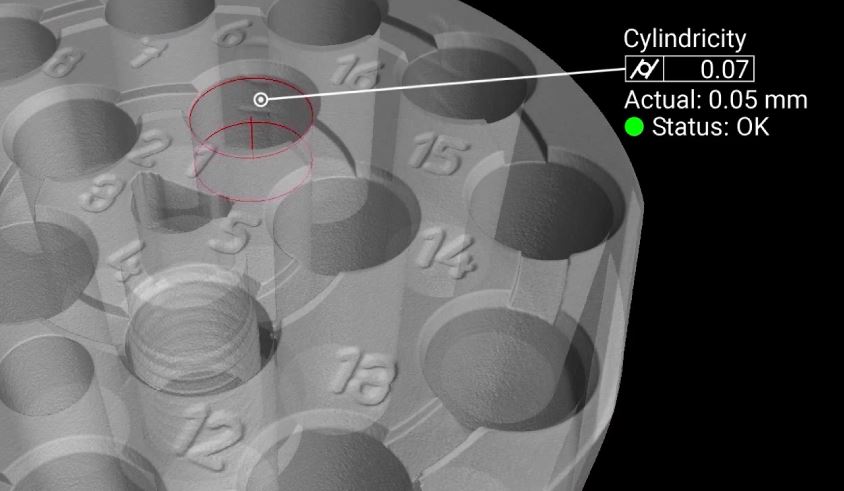

- GD&T (Geometric dimensional and tolerancing) analysis

-

Internal defect analysis

Dimensional analysis techniques

Dimensional analysis of cast, machined, or 3D printed parts is an important process of process control, failure analysis, and research and development. There are mainly three techniques to measure dimensions of complicated shapes:

- Coordinate measuring machine (CMM) - Mechanical and tactile measurement

- Optical scanner - Optical measurement

- X-ray Computed Tomography scanner (CT) - X-ray absorption-based measurement

Each technique has its pros and cons. A CMM is considered to be the most accurate, but it can measure only selected points on a surface. An optical scanner can measure the entire surface but cannot see any internal structure. An X-ray CT scanner can scan the entire volume, including the internal dimensions and defects, but the sample size is rather limited compared to the other two techniques.

All three techniques listed above, including X-ray CT, can analyze parts dimensions, such as the size of parts, diameter of a hole or cylinder, etc. You can also define XYZ coordinate and apply full GD&T analysis to test tolerances of various measurements.

Metrology Application Examples

Watch an on-demand webinar about X-ray CT metrology applications.

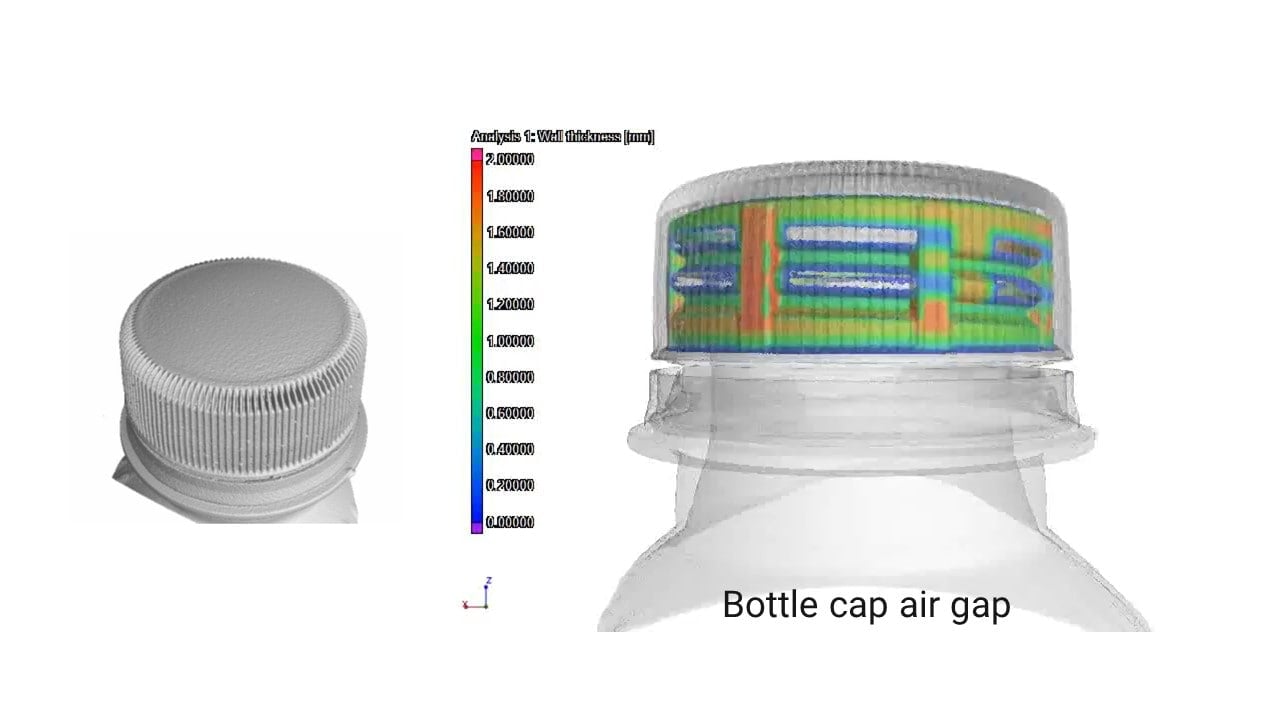

Bottlecap air gap analysis

Application Note

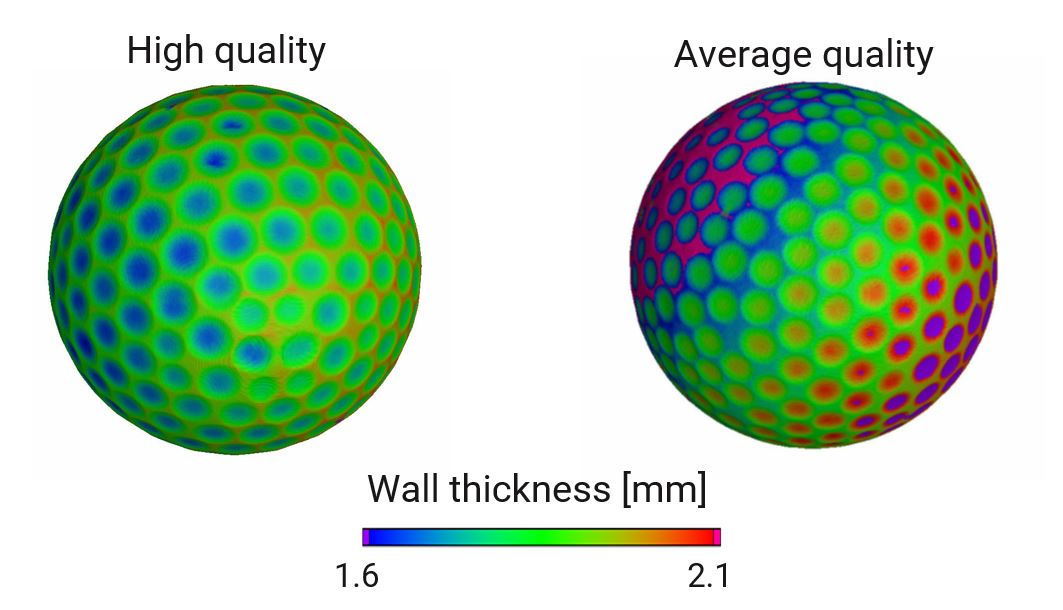

Golf ball layer thickness analysis

Application Note

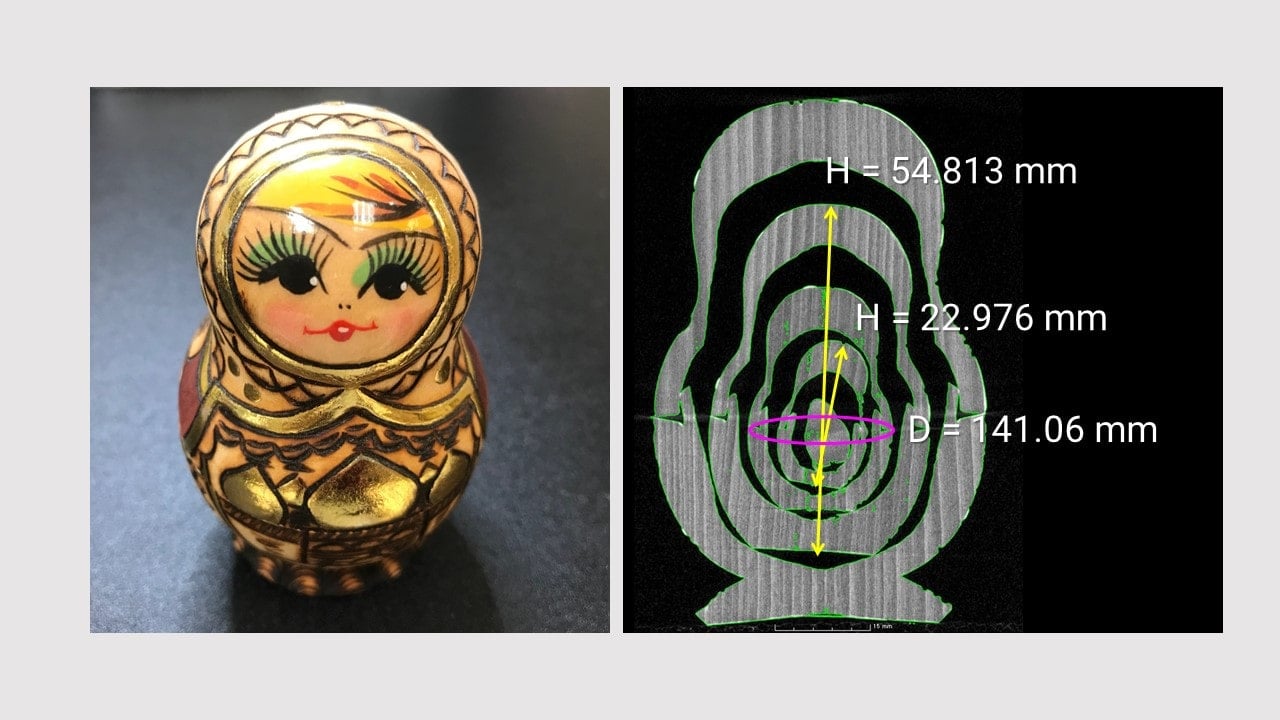

Nesting doll dimensional analysis

Application Note

Plastic parts quality control and reverse engineering

Application Note

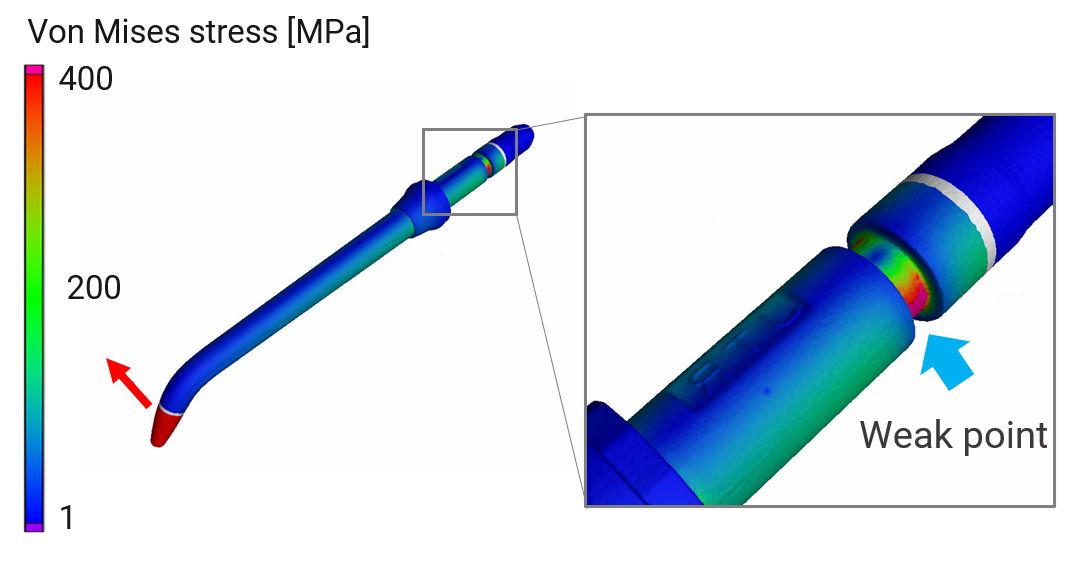

Water flosser tip stress simulation

Application Note

3D printed plastic dimensional analysis

Application Note

Aluminum die casting void analysis

Application Note

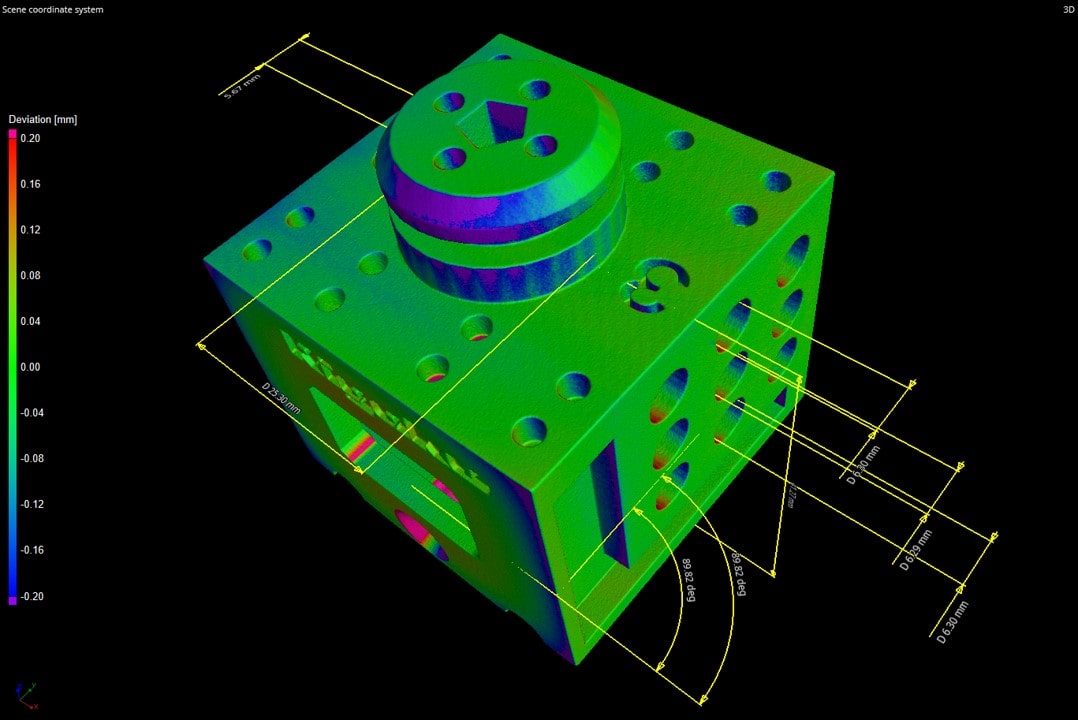

Aluminum part dimensional analysis

Application Note & Video

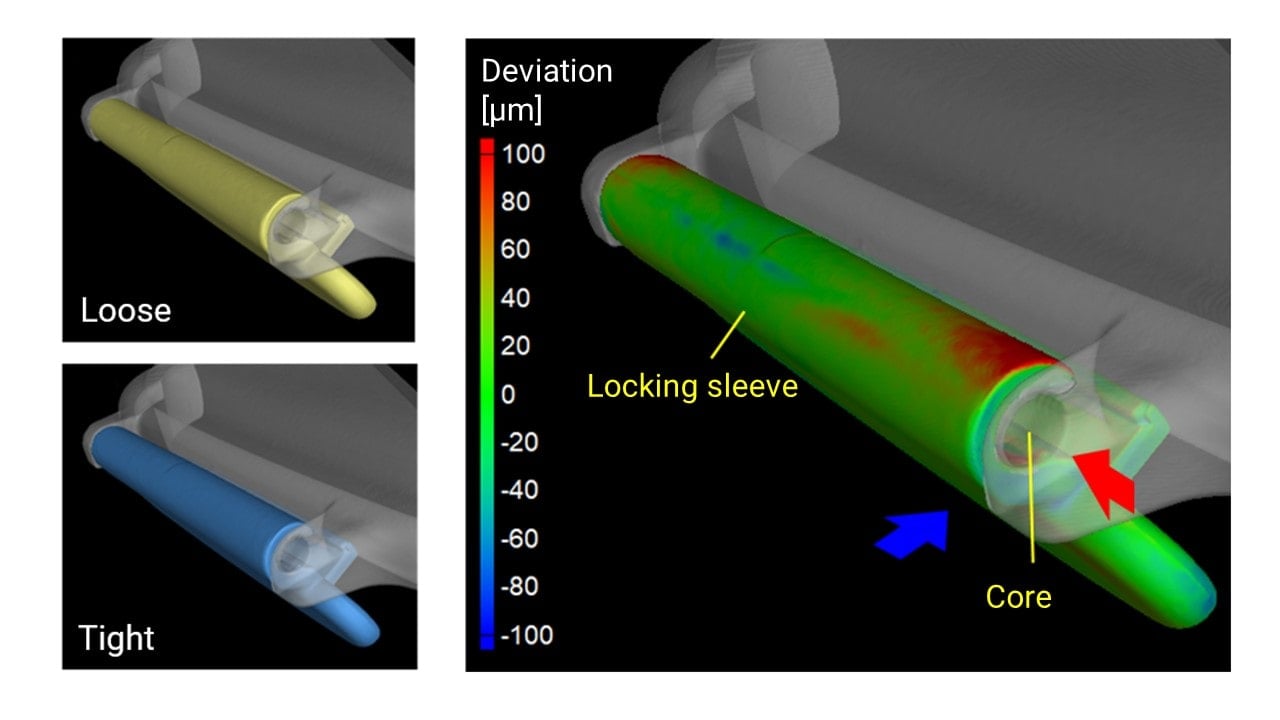

Plastic Locking Parts Dimensional Comparison

Application Note

What is micro-CT?

How does it work? How much does it cost? Do I need It? What are the common problems?

To learn everything you need to know about micro-CT, you can start here: What is micro-CT?