GOLF BALL LAYER THICKNESS ANALYSIS

About the sample: Golf balls

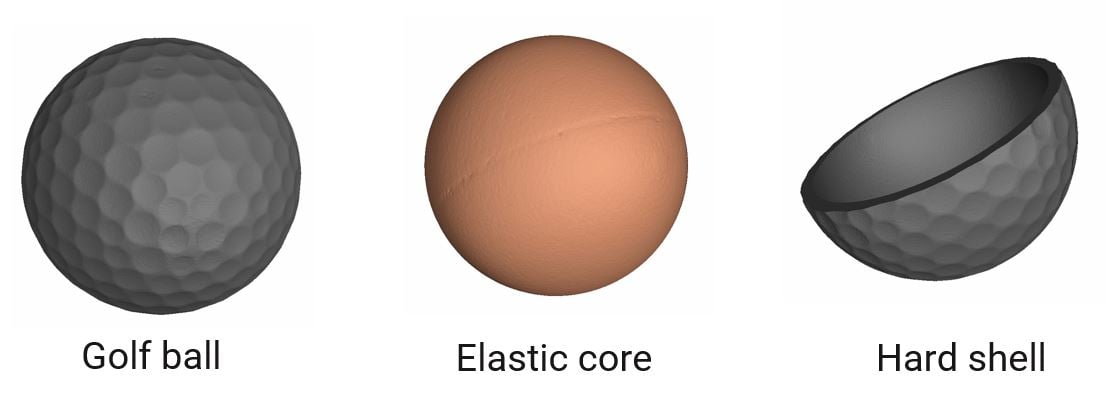

Multi-layered golf balls include a core, middle layer(s), and a cover coating with dimples. The properties of all components such as layer thickness and elasticity all affect the performance of the golf balls. A lot goes into the design of golf balls to improve the speed, distance, spin, lift, etc. However well you design a golf ball if the layers and cover are not centered to the core, the ball wouldn't perform well. The construction and alignment of golf balls can be analyzed using X-ray CT (computed tomography).

Analysis procedure

- In this example, two golf balls were scanned using a micro-CT scanner, CT Lab HX.

- The cover shapes were detected using the ISO-50 surface determination technique.

- The cover thickness distributions were analyzed to see how well centered the cores were.

1. CT scan

Two golf balls with different qualities were scanned to produce the 3D grayscale CT image.

2. Surface detection

The external surface and the cover/core interface were detected using the ISO-50 surface determination technique to separate the cover (hard shell with high density). A seam of the elastic core is seen in the middle.

3. Thickness distribution analysis

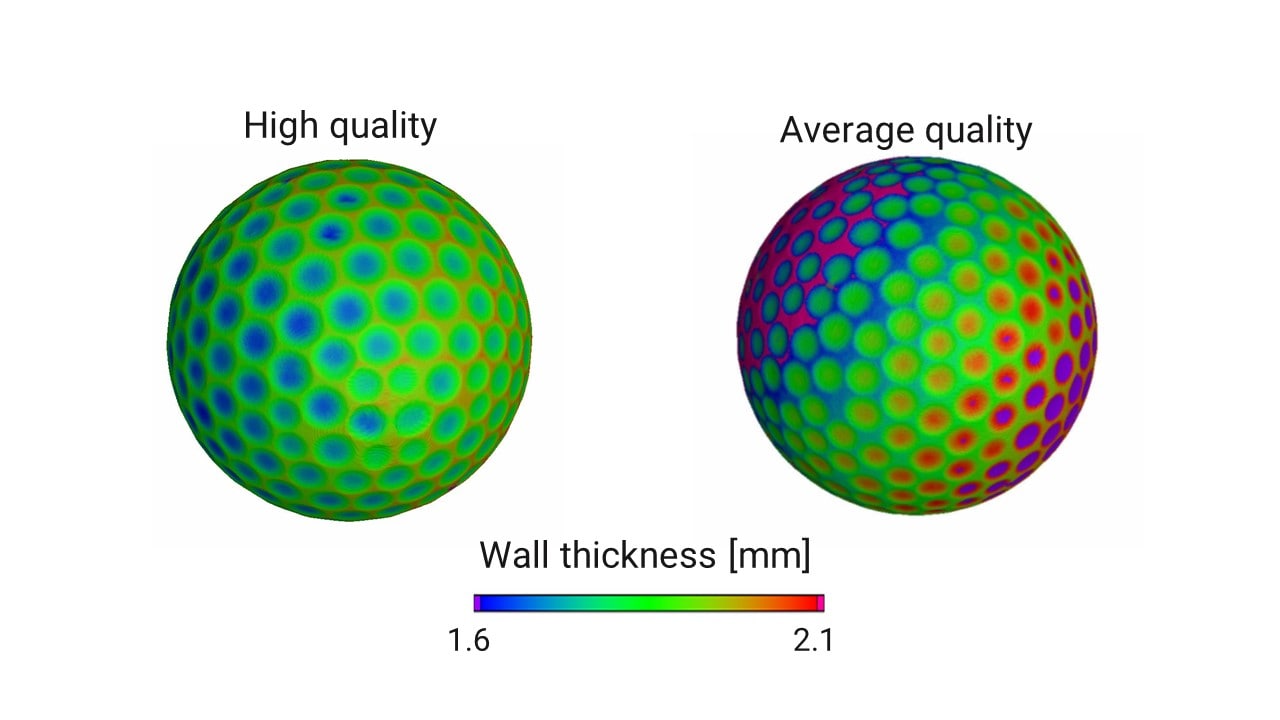

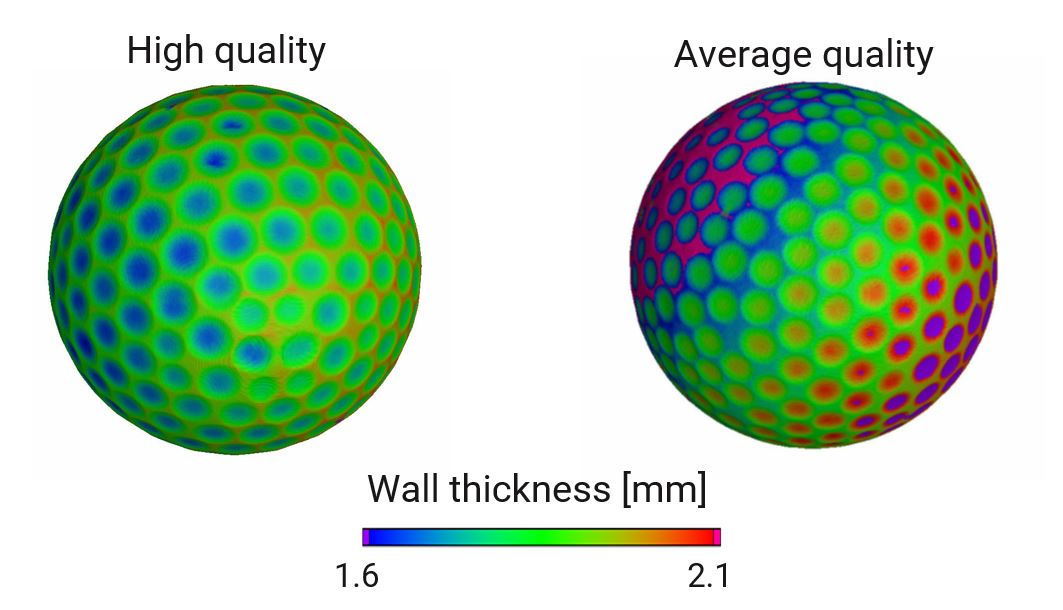

The cover wall thickness distributions were analyzed and the two golf balls with high and average qualities were compared. The wall thickness is color-coded from blue 1.6 mm to red 2.1 mm.

The high-quality golf ball showed a relatively uniform thickness distribution, indicating that the elastic core sits at the center of the ball. Meanwhile, the average quality golf ball showed a significant difference on the left and right sides, indicating that the elastic core is a few hundred microns off the ball center.

More Metrology Application Examples

Watch an on-demand webinar about X-ray CT metrology applications.

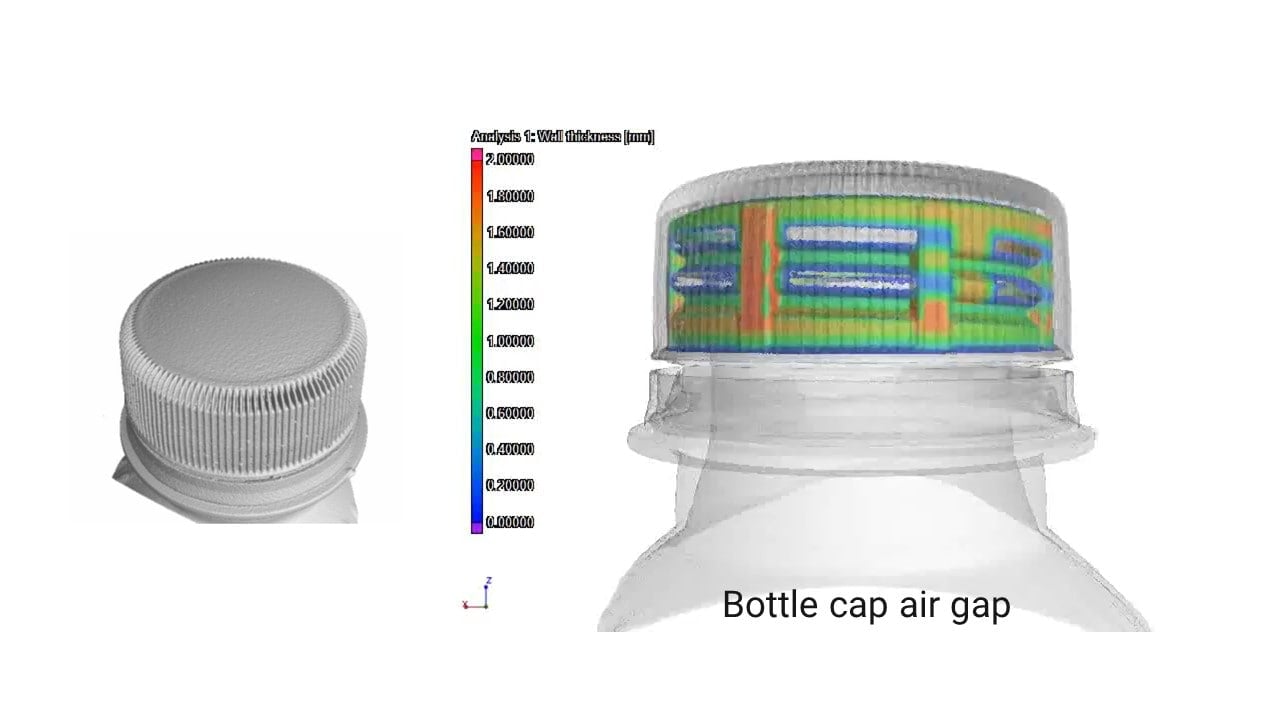

Bottlecap air gap analysis

Application Note

Golf ball layer thickness analysis

Application Note

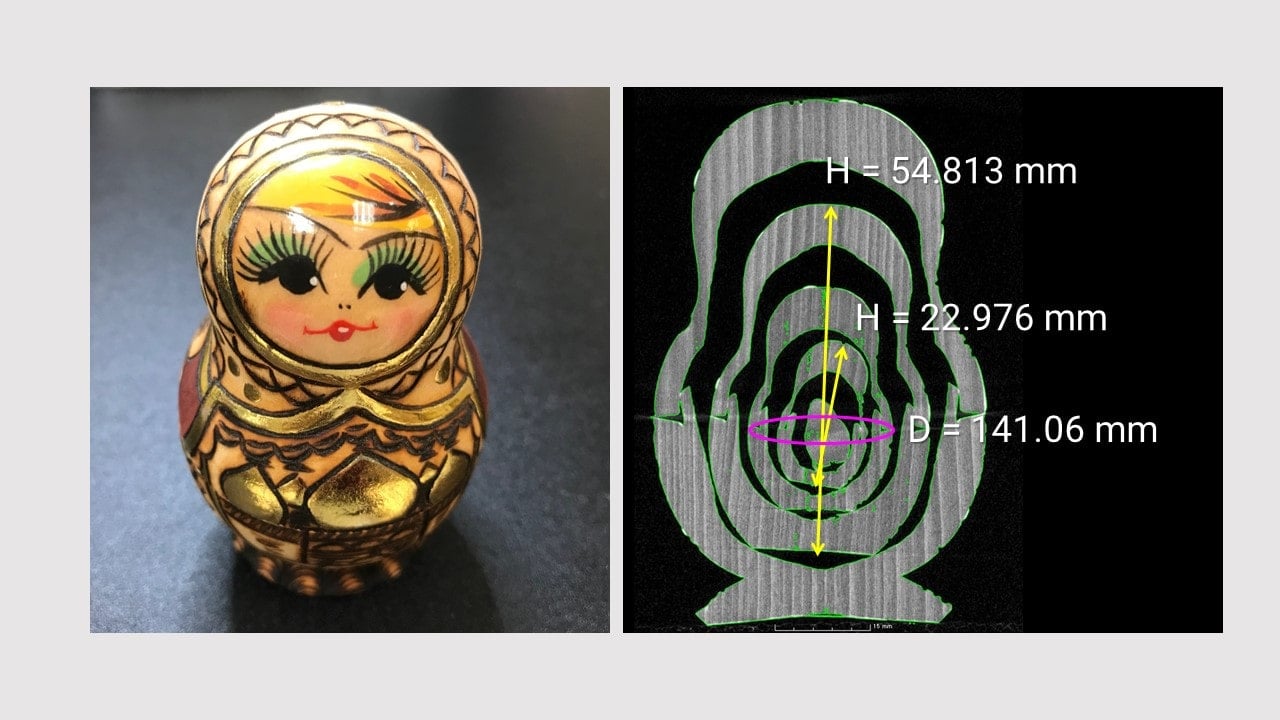

Nesting doll dimensional analysis

Application Note

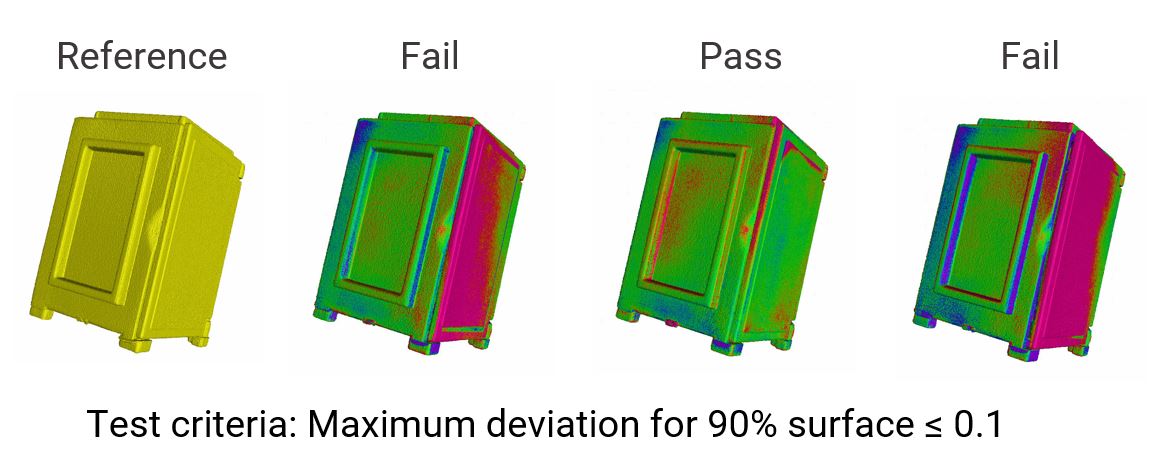

Plastic parts quality control and reverse engineering

Application Note

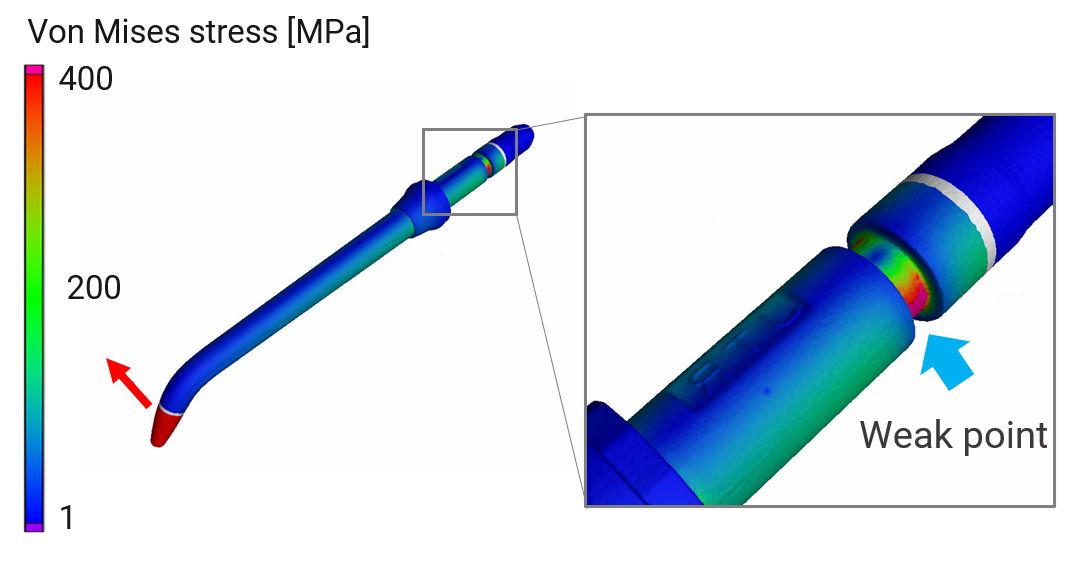

Water flosser tip stress simulation

Application Note

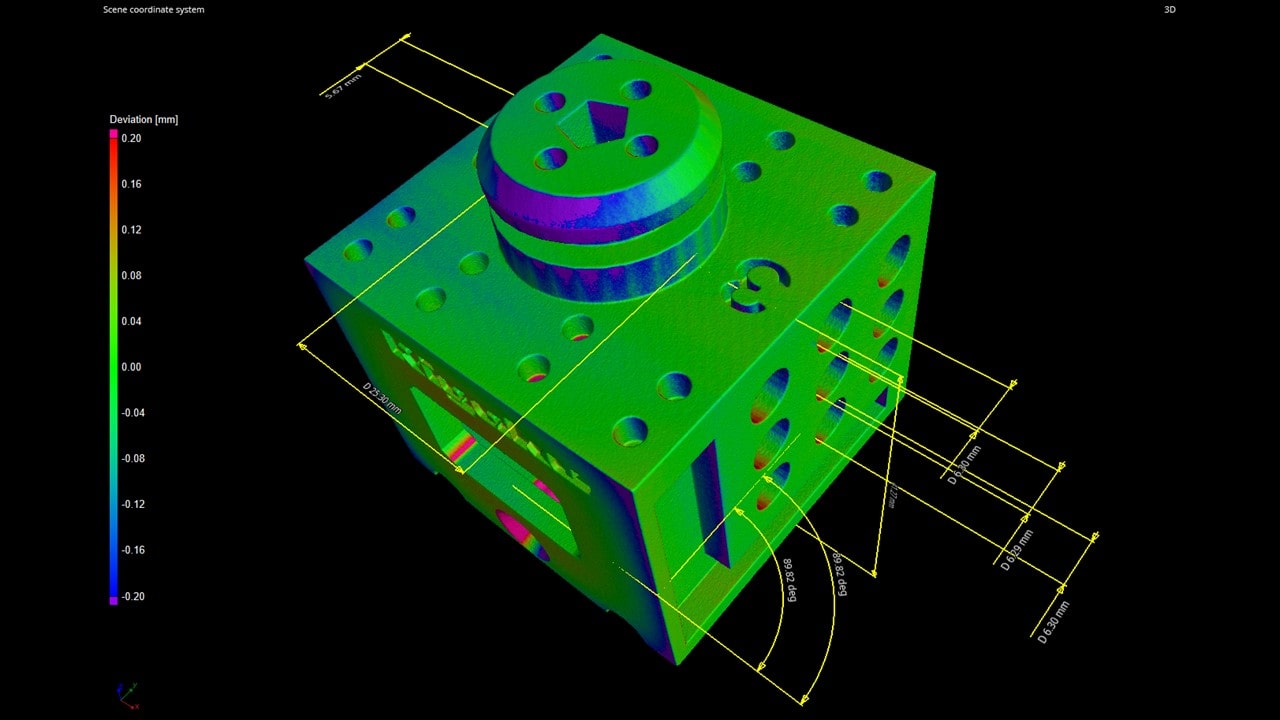

3D printed plastic dimensional analysis

Application Note

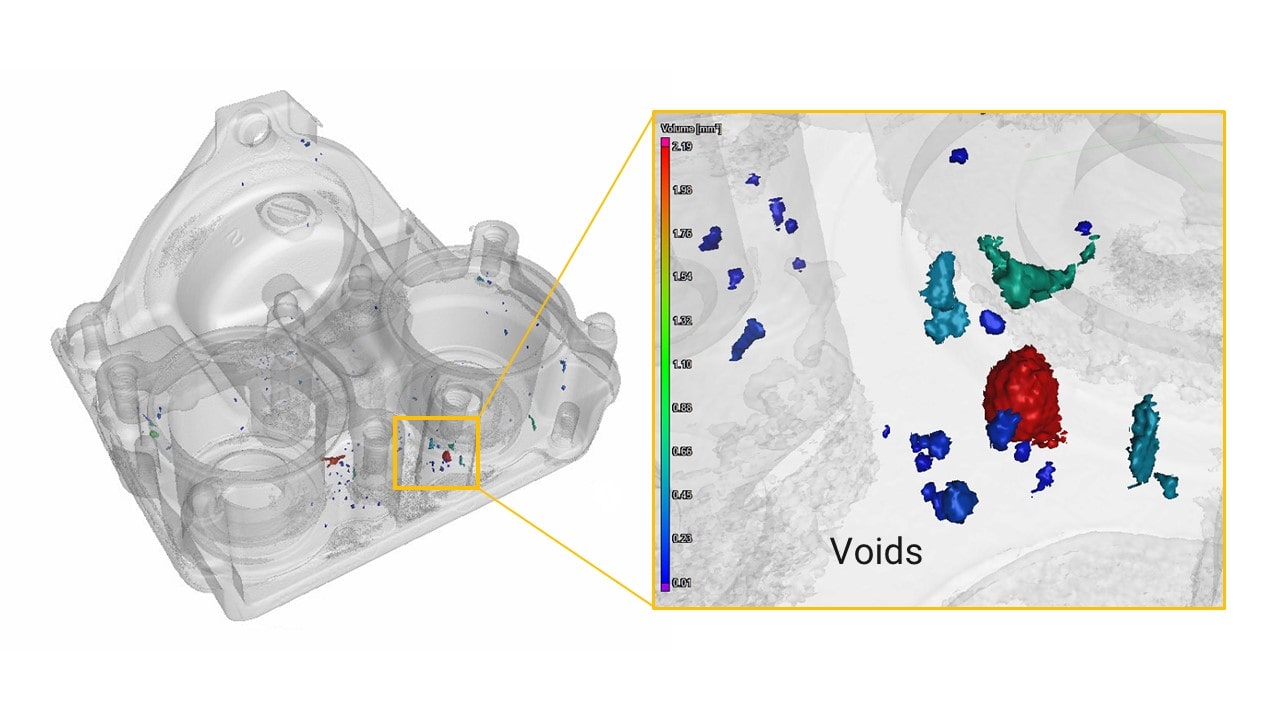

Aluminum die casting void analysis

Application Note

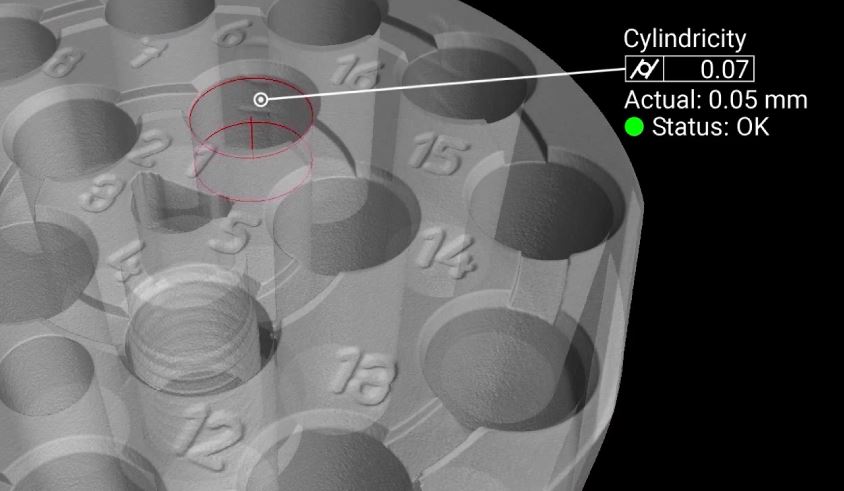

Aluminum part dimensional analysis

Application Note & Video

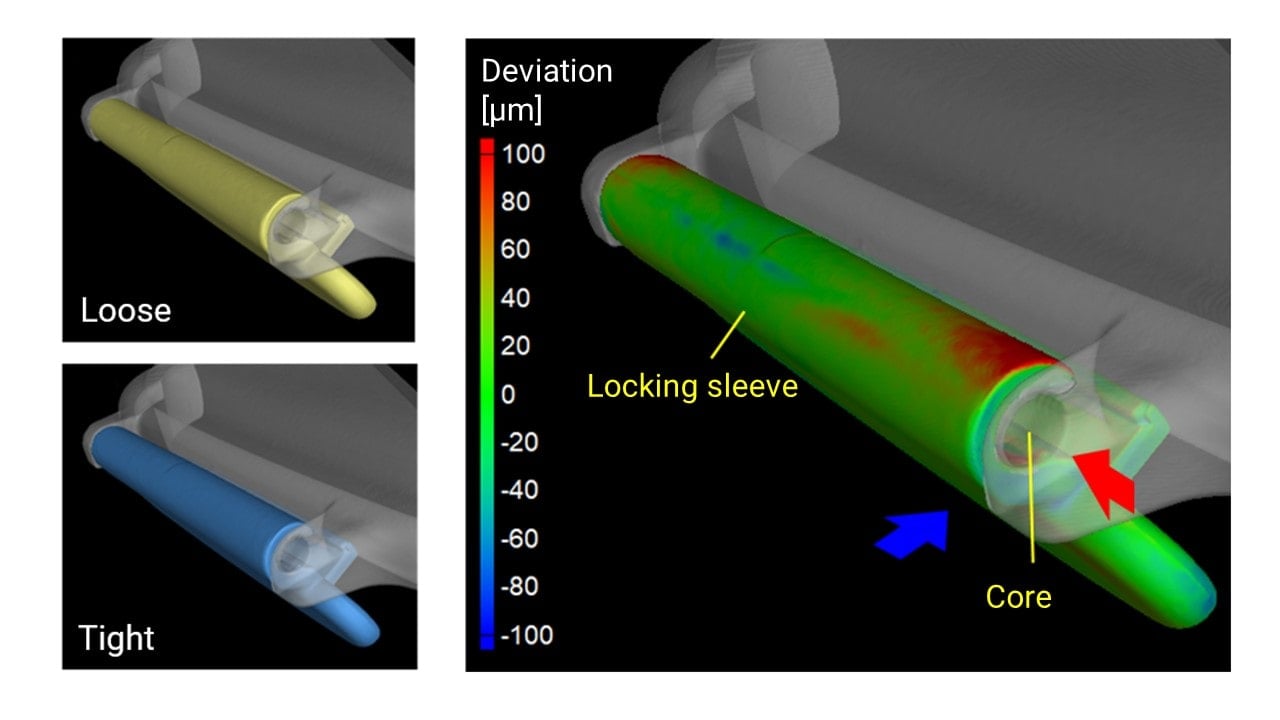

Plastic Locking Parts Dimensional Comparison

Application Note